Disclaimer: I don't have a clue what I am doing.

I am writing this mostly for my own benefit, I don't feel like I have made much progress with the project and so I think looking back on here in a few months’ time will help me realise how far we have come (hopefully!). But also... who dosen't like showing there Landy off!

So meet Cynthia. We bought Cynthia in August 2018, the previous owners named her and I believe its to do with the last three letters of the number plate. She is a 1997 300tdi Station Wagon, I personally would of chosen a 90, but my partner wanted something 'future proof' *gulp* ... at least she can’t tell me to get rid of it now!

August to September 2018

We had a good look around and the only thing we could see was that the back door and rear passenger doors were slightly rusty oh and the exhaust pipe needed replacing after I brushed past it and a foot long section fell off to echoes of the owner saying "There aint nout wrong with that". All looked good, so we bought her home.

Turns out we really do know nothing! The previous owner was kind enough to give us half a tank of fuel for the journey home, the next day we filled her up in the rain, and when we parked her up at home it looked like the Torrey Canyon had paid us a visit. A few panic posts on this forum later and I worked out it was the sender valve.

As I didnt know what I was doing (I didn't even have a tool kit at this point!) I sent it to the garage and asked them to sort that out, the exhaust pipe and give it a good once over to see if they can spot anything.

I wish I never asked them.

They spotted two holes behind the rear springs about the size of a 50p coin. I honestly would of never have spotted them, they only became visible when it was up on the ramps and the axle extended. So, this leads to the first argument that me and my partner have had about "what the hell are we doing".

I spoke to quite a few local people and in the end spoke to Craig at Buzzweld - a bit further for us to travel, but we wanted the chassis treated anyway, two birds one stone. Craig had a good look for us but sadly the bad news came back, there was a few more weak spots and he pointed us in the direction of Steve at SAS Welding where we all discussed what to do.

In the end it was concluded that a new rear half chassis is the best course of action. Yes the holes can be repaired, but I will probably end up back there in 2 or three years’ time with a few more and so on it goes. I would rather pay more now to have something I don’t have to constantly worry about.

October 2018

For various reasons we had to put Steve off doing the work, well I will tell you the truth, I crashed my daily car and needed that for work, I was not sure when I would get it back so I delayed Steve for the foreseeable – but we paid for the chassis so that could be ordered and ready to go.

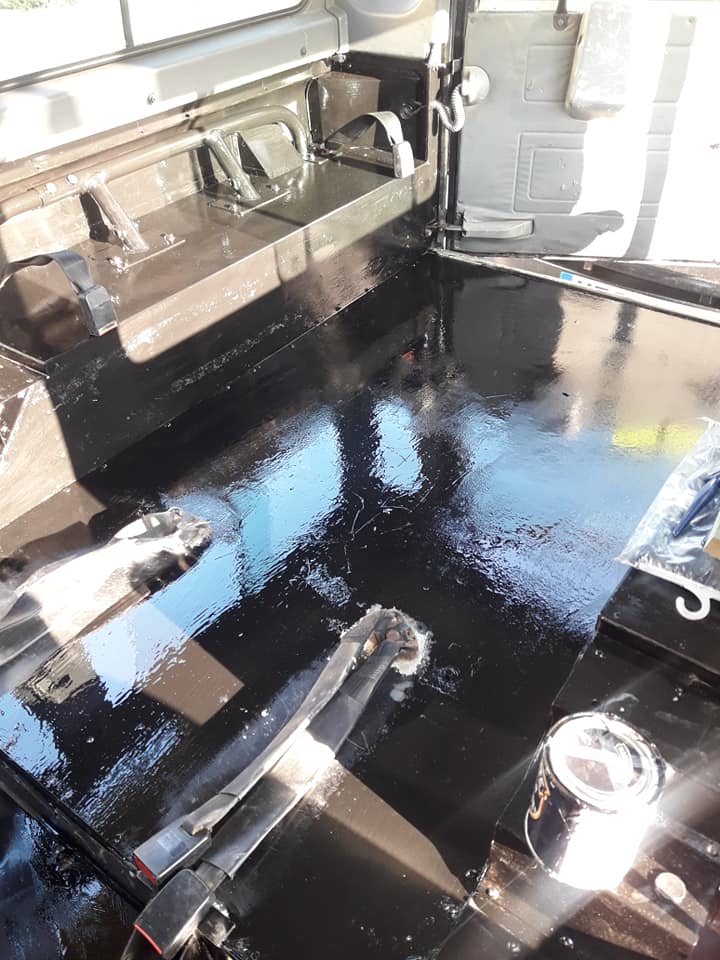

In the meanwhile we spent our time tidying her up, the previous owners had dogs and though the outside looks lovey the inside is a bit gnarly. The entire of the back was stripped out, sanded down, washed, a few holes filled, painted with hammerite*, sanded, painted, sanded, painted…. And it went on…. Some of the lovely comments we received consisted of “It smells like old shed in here” & “how do you drive this and not see sounds and hear colours?”

*Knowing what I know now, I would of not used hammerite, but-hey-ho, learning curve and all that.

By the end of it, if you could stand the smell, it actually looked quite nice! I was also gifted my grandads old tools, he sadly passes away in August 2017 so didn’t have much of a use for them. He served his time in the Navy; turns out most of his tools were also ‘borrowed’ from Her Maj. too!

We decided we wanted to sound proof the Landrover and after looking at various options came across something called DeadSheet from a local company Oxford Sound Services. Deadsheet sold itself not as soundproofing, but as sound deadening, the idea is to not necessarily make things quieter but to stop the drumming effect of the metal.

I made quite quick progress on this, the rear load area was soon covered, as the sheets were large. What took the time was the tiny little fiddly bits, several thumbs and dozens of knife blades later and I am still not finished with the sound proofing. I have got as far as the front of the middle row floor panel and lost all interest since. It’s boring, its time consuming, and I hate it.

November 2018

November was the first time I truly experienced what Landrover ownership was like. I used to work on an estate growing up so was constantly exposed to landrover…. But when they broke they went to the mechanic, never have I had to fix one before.

The first issue started on a long drive up to Derbyshire, the battery light was faintly glowing. I pulled over, opened the bonnet, saw the engine was still there, closed the bonnet. I knew nothing else! I had heard on various forums that the battery sometimes does not charge properly if sitting idle and as I had been in stationary traffic that’s what I put it down to. Once on the motorway I floored it and the light went off. Problem solved.

Three days later on my way home, in the dark, whilst raining, on the motorway, I noticed I could not see anything. I am used to not being able to see anything, but that’s normally due to the hammerite fumes making my eyes water. This was a kid of different not being able to see, a ‘my headlights and window screen lights are not working’ kind of thing. I pulled over in some services and turned the engine off. Unsurprisingly it didn’t start back up. So on the phone to the AA. AA chap turned up and after a bit of looking decided it was the alternator. He charged my battery up and gave me the best piece of advice I have been given on landrover maintenance to date “If you have any issues on the way home, pull over and hit it with a lump hammer”. I managed to crawl back home, just.

Annoyingly the Landy would not start the next day, and I had a week of site work to do so desperately needed it so off to the garage again. The alternator was the original 1997 45A one, so did not owe me much, it has now been replaced with a 65A one.

All was well in the world, until we went to the Coventry Landrover show. We had a great day out, until we tried to go home. The engine would not start, it would turn over but that’s all. I tried all the usual suspects, nothing seemed to work until all of a sudden it just started?! At this point I should say a huge thank you to the Disco owner and family parked behind us who were stationed with the jump leads ready! Just goes to show what a lovely community it is.

We didn’t have a clue what it was, at the time we thought we might have left something on. But it became apparent a few weeks later. I drove to a site up in Leistershire, no issue, turn the landy off, sign in, and guess what…. Dead. It would not even turn over.

Lucky the site I was at is full of experienced fitters and landrovers fans, so he had a look for me and informed me it was the starter motor and if I have any issues just shove a screw driver in here. I even spotted this whilst I was there...

This was fine for about a week, it would fail to start once every 4 or 5 starts maybe, but the trick he told me worked well. That is until next week, same site, I drove out about a mile from the site office turned the engine off and when I came back it would turn over but not start. I tried everything. In the end a passing 30 ton articulated dump truck gave me the most terrifying tow of my life back to the car park, but even bump starting it I couldn’t get it to go….. gotta be the fuel system then. I dismantled everything I could lay my hands on, at this point I should point out it was done with a £1.50 adjustable spanner, a pair of 1945 dated mole grips and a screw driver that wouldn’t be fit to stir paint with.

In the end it turned out to be the fuel stop solenoid. I removed the pin from that and away we went. It just means I had to stall it to stop the engine now. I phoned a local garage to order me a new one in and went down there the next day, they offered to fit it free of charge, so took them up on that. But still they could not make it work. A volt meter gave the game away in the end as the solenoid was only drawing 9v instead of 12v. He said “It’s an immobiliser issue, your doomed”

December 2018

I spent most of December hiding from the idea of solving the immobiliser issue. It seems to be really common in 300tdi disco’s but not defenders for some reason. I bought a disco bypass and set away hacking at the immobiliser box in the battery compartment. After a few hours and spilt blood later I nearly resorted to finding a criminal to break into it as they seem to do it so easily.

Angle grinder…. No chance, area is too small. Big hack saw… no chance, too long. Even the little hacksaw wasn’t cutting it…. Cutting it…. HA…. Hand tool puns….. After a few hours I got into it, problem was obvious, a blown component, bypass put in. Solenoid wire reading 12v again. Job done, now all I need to do is put the pin back into the solenoid and away we go for tea and medals.

Like hell could I get the solenoid off again? The last garage had rounded it off more than a really round thing. In the end I resorted to going to a local garage and asking them to get it off for me. The chap said “You are only asking me to do this, because if I break it it’s my problem” at which point I proudly said “Yes!”. Eventually they managed to get it off, and away we went. Touch wood, we have not had any mechanical issues since.

January 2019

January was a surprisingly good month, my father, a very experienced carpenter and joiner produced a set of draws that sit between the wheel arches. This marked the start of our overland build, the aim is to still have a reasonable day to day vehicle, but be quipped and fitted with enough kit that we can just pack up and roll out whenever we feel.

Due to the availability of draw runners, we have a long deep draw at the front, a pull out table shelf thingy below and a 300mm’ish by 500mm’ish compartment behind it which will be great for all those “what if” things.

I also began to cover the top of the draw and wheel arches with 3mm rubber mat. This will not only keep the dirt off the draw but also offer us something that we can easily keep clean. This was a job I was dreading. It’s like sound proofing all over again, but with larger sheets and more stupid angles. We used a B&Q own brand ‘stick rubber to anything’ glue, which worked well where the rubber was in contact with the sound proofing, but it would not stick to the MDF of the draw. The only thing my father and I can put this down to is the MDF was not treated so the glue just absorbed straight into the MDF instead. So we went for plan B. Using the age old phrase “If it canney be stuck with ye silicone, canney be stuck at all” about 6 tubes later and its mostly stuck. There are odd places on the corners especially where it is peeling up slightly. But I left them as I was getting in such a mess I decided I would let it all dry first then sort it out later.

Like usual, I haven’t finished the job. The corners still need sticking down and a couple of bits need finishing off here. But for the most part it is done. I ran a bead of black silicone around the edge so (in theory) the top is waterproof. But in places I made a bit of a mess of it so it needs redoing or at least touching up.

In January I also got in touch with Steve again about the chassis, it’s now booked in to be with him for the 16th Feb. We decided a long while back to replace a lot of the chassis components as there is no point putting crap back onto a lovely nice clean chassis. Both to keep cost down and to ensure we get what we want we bought the components and he will fit them:

- Copper brake lines all around

- +2 brake hoses all around

- Britpart +2mm suspension kit (inc. trailing arms etc)

- Devon 4x4 +2 turrets

I think that’s all. I was going to do the suspension myself, but as he needs to take it off to access what he is doing, he said he will put the new back on. I am still undecided if going for the Britpart +2 is a good idea or not, worst case scenario I can always take it off…. The chief decision maker demanded that we either get yellow springs or ‘you better get out there with a paint brush’…. So yellow springs it is then!

I have not done much this month, we have been doing a lot of family stuff and also been on a few nice hikes away so whilst working 9 to 5 and no covered garage or driveway to work on I really don’t have the opportunity once home during the evening.

February 2019

The beginning of February has seemed to have escaped me. I have not done anything of any interest. I replaced the aux drive belt as it was squeaking, but that’s about it.

I did speak to TuffRoc about ordering some shiny new mud flaps (yellow and black of course!) as even though Cynthia came with 4, she is down to only 2 inches of one now. I always wonder what it must be like for the driver behind me when my mudflap and bracket comes flying towards them. Hummm.

As the Landy is off to Steve on Saturday and I still have not finished fixing my car, I better do that job otherwise its walking 10 miles to work every day. For some reason I just can’t find any motivation, I am happy to do things on the landrover, but my own car I couldn’t care less about…. That’s all it is to me… a car.

We are off to Scotland in April for 19 days, so a mad rush has begun to try and sort things for that. There is quite a few things I want to fit to the landy before we go, we will see how much gets done! Most important is an awning, what expedition vehicle is complete without an awning! Annoyingly it’s also the most expensive thing. Some sort of dog cage would be good in the back too, I have noticed that with the new draw things just go flying off the back and under the middle row seat. Trying to find one that will fit, locally, and is cheap is a lot harder than you think!

Anyway, congratulations if you have made is this far, that’s all we have done so far, plenty (list and lists!) to go and I hope to update this when I can.

I am writing this mostly for my own benefit, I don't feel like I have made much progress with the project and so I think looking back on here in a few months’ time will help me realise how far we have come (hopefully!). But also... who dosen't like showing there Landy off!

So meet Cynthia. We bought Cynthia in August 2018, the previous owners named her and I believe its to do with the last three letters of the number plate. She is a 1997 300tdi Station Wagon, I personally would of chosen a 90, but my partner wanted something 'future proof' *gulp* ... at least she can’t tell me to get rid of it now!

August to September 2018

We had a good look around and the only thing we could see was that the back door and rear passenger doors were slightly rusty oh and the exhaust pipe needed replacing after I brushed past it and a foot long section fell off to echoes of the owner saying "There aint nout wrong with that". All looked good, so we bought her home.

Turns out we really do know nothing! The previous owner was kind enough to give us half a tank of fuel for the journey home, the next day we filled her up in the rain, and when we parked her up at home it looked like the Torrey Canyon had paid us a visit. A few panic posts on this forum later and I worked out it was the sender valve.

As I didnt know what I was doing (I didn't even have a tool kit at this point!) I sent it to the garage and asked them to sort that out, the exhaust pipe and give it a good once over to see if they can spot anything.

I wish I never asked them.

They spotted two holes behind the rear springs about the size of a 50p coin. I honestly would of never have spotted them, they only became visible when it was up on the ramps and the axle extended. So, this leads to the first argument that me and my partner have had about "what the hell are we doing".

I spoke to quite a few local people and in the end spoke to Craig at Buzzweld - a bit further for us to travel, but we wanted the chassis treated anyway, two birds one stone. Craig had a good look for us but sadly the bad news came back, there was a few more weak spots and he pointed us in the direction of Steve at SAS Welding where we all discussed what to do.

In the end it was concluded that a new rear half chassis is the best course of action. Yes the holes can be repaired, but I will probably end up back there in 2 or three years’ time with a few more and so on it goes. I would rather pay more now to have something I don’t have to constantly worry about.

October 2018

For various reasons we had to put Steve off doing the work, well I will tell you the truth, I crashed my daily car and needed that for work, I was not sure when I would get it back so I delayed Steve for the foreseeable – but we paid for the chassis so that could be ordered and ready to go.

In the meanwhile we spent our time tidying her up, the previous owners had dogs and though the outside looks lovey the inside is a bit gnarly. The entire of the back was stripped out, sanded down, washed, a few holes filled, painted with hammerite*, sanded, painted, sanded, painted…. And it went on…. Some of the lovely comments we received consisted of “It smells like old shed in here” & “how do you drive this and not see sounds and hear colours?”

*Knowing what I know now, I would of not used hammerite, but-hey-ho, learning curve and all that.

By the end of it, if you could stand the smell, it actually looked quite nice! I was also gifted my grandads old tools, he sadly passes away in August 2017 so didn’t have much of a use for them. He served his time in the Navy; turns out most of his tools were also ‘borrowed’ from Her Maj. too!

We decided we wanted to sound proof the Landrover and after looking at various options came across something called DeadSheet from a local company Oxford Sound Services. Deadsheet sold itself not as soundproofing, but as sound deadening, the idea is to not necessarily make things quieter but to stop the drumming effect of the metal.

I made quite quick progress on this, the rear load area was soon covered, as the sheets were large. What took the time was the tiny little fiddly bits, several thumbs and dozens of knife blades later and I am still not finished with the sound proofing. I have got as far as the front of the middle row floor panel and lost all interest since. It’s boring, its time consuming, and I hate it.

November 2018

November was the first time I truly experienced what Landrover ownership was like. I used to work on an estate growing up so was constantly exposed to landrover…. But when they broke they went to the mechanic, never have I had to fix one before.

The first issue started on a long drive up to Derbyshire, the battery light was faintly glowing. I pulled over, opened the bonnet, saw the engine was still there, closed the bonnet. I knew nothing else! I had heard on various forums that the battery sometimes does not charge properly if sitting idle and as I had been in stationary traffic that’s what I put it down to. Once on the motorway I floored it and the light went off. Problem solved.

Three days later on my way home, in the dark, whilst raining, on the motorway, I noticed I could not see anything. I am used to not being able to see anything, but that’s normally due to the hammerite fumes making my eyes water. This was a kid of different not being able to see, a ‘my headlights and window screen lights are not working’ kind of thing. I pulled over in some services and turned the engine off. Unsurprisingly it didn’t start back up. So on the phone to the AA. AA chap turned up and after a bit of looking decided it was the alternator. He charged my battery up and gave me the best piece of advice I have been given on landrover maintenance to date “If you have any issues on the way home, pull over and hit it with a lump hammer”. I managed to crawl back home, just.

Annoyingly the Landy would not start the next day, and I had a week of site work to do so desperately needed it so off to the garage again. The alternator was the original 1997 45A one, so did not owe me much, it has now been replaced with a 65A one.

All was well in the world, until we went to the Coventry Landrover show. We had a great day out, until we tried to go home. The engine would not start, it would turn over but that’s all. I tried all the usual suspects, nothing seemed to work until all of a sudden it just started?! At this point I should say a huge thank you to the Disco owner and family parked behind us who were stationed with the jump leads ready! Just goes to show what a lovely community it is.

We didn’t have a clue what it was, at the time we thought we might have left something on. But it became apparent a few weeks later. I drove to a site up in Leistershire, no issue, turn the landy off, sign in, and guess what…. Dead. It would not even turn over.

Lucky the site I was at is full of experienced fitters and landrovers fans, so he had a look for me and informed me it was the starter motor and if I have any issues just shove a screw driver in here. I even spotted this whilst I was there...

This was fine for about a week, it would fail to start once every 4 or 5 starts maybe, but the trick he told me worked well. That is until next week, same site, I drove out about a mile from the site office turned the engine off and when I came back it would turn over but not start. I tried everything. In the end a passing 30 ton articulated dump truck gave me the most terrifying tow of my life back to the car park, but even bump starting it I couldn’t get it to go….. gotta be the fuel system then. I dismantled everything I could lay my hands on, at this point I should point out it was done with a £1.50 adjustable spanner, a pair of 1945 dated mole grips and a screw driver that wouldn’t be fit to stir paint with.

In the end it turned out to be the fuel stop solenoid. I removed the pin from that and away we went. It just means I had to stall it to stop the engine now. I phoned a local garage to order me a new one in and went down there the next day, they offered to fit it free of charge, so took them up on that. But still they could not make it work. A volt meter gave the game away in the end as the solenoid was only drawing 9v instead of 12v. He said “It’s an immobiliser issue, your doomed”

December 2018

I spent most of December hiding from the idea of solving the immobiliser issue. It seems to be really common in 300tdi disco’s but not defenders for some reason. I bought a disco bypass and set away hacking at the immobiliser box in the battery compartment. After a few hours and spilt blood later I nearly resorted to finding a criminal to break into it as they seem to do it so easily.

Angle grinder…. No chance, area is too small. Big hack saw… no chance, too long. Even the little hacksaw wasn’t cutting it…. Cutting it…. HA…. Hand tool puns….. After a few hours I got into it, problem was obvious, a blown component, bypass put in. Solenoid wire reading 12v again. Job done, now all I need to do is put the pin back into the solenoid and away we go for tea and medals.

Like hell could I get the solenoid off again? The last garage had rounded it off more than a really round thing. In the end I resorted to going to a local garage and asking them to get it off for me. The chap said “You are only asking me to do this, because if I break it it’s my problem” at which point I proudly said “Yes!”. Eventually they managed to get it off, and away we went. Touch wood, we have not had any mechanical issues since.

January 2019

January was a surprisingly good month, my father, a very experienced carpenter and joiner produced a set of draws that sit between the wheel arches. This marked the start of our overland build, the aim is to still have a reasonable day to day vehicle, but be quipped and fitted with enough kit that we can just pack up and roll out whenever we feel.

Due to the availability of draw runners, we have a long deep draw at the front, a pull out table shelf thingy below and a 300mm’ish by 500mm’ish compartment behind it which will be great for all those “what if” things.

I also began to cover the top of the draw and wheel arches with 3mm rubber mat. This will not only keep the dirt off the draw but also offer us something that we can easily keep clean. This was a job I was dreading. It’s like sound proofing all over again, but with larger sheets and more stupid angles. We used a B&Q own brand ‘stick rubber to anything’ glue, which worked well where the rubber was in contact with the sound proofing, but it would not stick to the MDF of the draw. The only thing my father and I can put this down to is the MDF was not treated so the glue just absorbed straight into the MDF instead. So we went for plan B. Using the age old phrase “If it canney be stuck with ye silicone, canney be stuck at all” about 6 tubes later and its mostly stuck. There are odd places on the corners especially where it is peeling up slightly. But I left them as I was getting in such a mess I decided I would let it all dry first then sort it out later.

Like usual, I haven’t finished the job. The corners still need sticking down and a couple of bits need finishing off here. But for the most part it is done. I ran a bead of black silicone around the edge so (in theory) the top is waterproof. But in places I made a bit of a mess of it so it needs redoing or at least touching up.

In January I also got in touch with Steve again about the chassis, it’s now booked in to be with him for the 16th Feb. We decided a long while back to replace a lot of the chassis components as there is no point putting crap back onto a lovely nice clean chassis. Both to keep cost down and to ensure we get what we want we bought the components and he will fit them:

- Copper brake lines all around

- +2 brake hoses all around

- Britpart +2mm suspension kit (inc. trailing arms etc)

- Devon 4x4 +2 turrets

I think that’s all. I was going to do the suspension myself, but as he needs to take it off to access what he is doing, he said he will put the new back on. I am still undecided if going for the Britpart +2 is a good idea or not, worst case scenario I can always take it off…. The chief decision maker demanded that we either get yellow springs or ‘you better get out there with a paint brush’…. So yellow springs it is then!

I have not done much this month, we have been doing a lot of family stuff and also been on a few nice hikes away so whilst working 9 to 5 and no covered garage or driveway to work on I really don’t have the opportunity once home during the evening.

February 2019

The beginning of February has seemed to have escaped me. I have not done anything of any interest. I replaced the aux drive belt as it was squeaking, but that’s about it.

I did speak to TuffRoc about ordering some shiny new mud flaps (yellow and black of course!) as even though Cynthia came with 4, she is down to only 2 inches of one now. I always wonder what it must be like for the driver behind me when my mudflap and bracket comes flying towards them. Hummm.

As the Landy is off to Steve on Saturday and I still have not finished fixing my car, I better do that job otherwise its walking 10 miles to work every day. For some reason I just can’t find any motivation, I am happy to do things on the landrover, but my own car I couldn’t care less about…. That’s all it is to me… a car.

We are off to Scotland in April for 19 days, so a mad rush has begun to try and sort things for that. There is quite a few things I want to fit to the landy before we go, we will see how much gets done! Most important is an awning, what expedition vehicle is complete without an awning! Annoyingly it’s also the most expensive thing. Some sort of dog cage would be good in the back too, I have noticed that with the new draw things just go flying off the back and under the middle row seat. Trying to find one that will fit, locally, and is cheap is a lot harder than you think!

Anyway, congratulations if you have made is this far, that’s all we have done so far, plenty (list and lists!) to go and I hope to update this when I can.