Marney96

Member

- Posts

- 18

- Location

- Staffordshire

Hi,

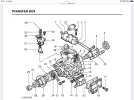

My front output shaft bearing is shagged on my Lt230 Defender (presumably by previous owner running big tyres and lift kit, now removed) I’m trying to pull the shaft out of the box but it won’t budge at all I’ve tried pullers, leverage, hammer and leverage, slide hammer to name a few. I’m starting to realise that I’m probably going to have to split the output housing from the main box and was wondering if this can be done in situ? To me it looks like a few 10mm bolts and a bolt that holds it do the chassis? Any advice would be greatly appreciated .

.

My front output shaft bearing is shagged on my Lt230 Defender (presumably by previous owner running big tyres and lift kit, now removed) I’m trying to pull the shaft out of the box but it won’t budge at all I’ve tried pullers, leverage, hammer and leverage, slide hammer to name a few. I’m starting to realise that I’m probably going to have to split the output housing from the main box and was wondering if this can be done in situ? To me it looks like a few 10mm bolts and a bolt that holds it do the chassis? Any advice would be greatly appreciated