Flossie

Well-Known Member

- Posts

- 11,398

- Location

- Shropshire

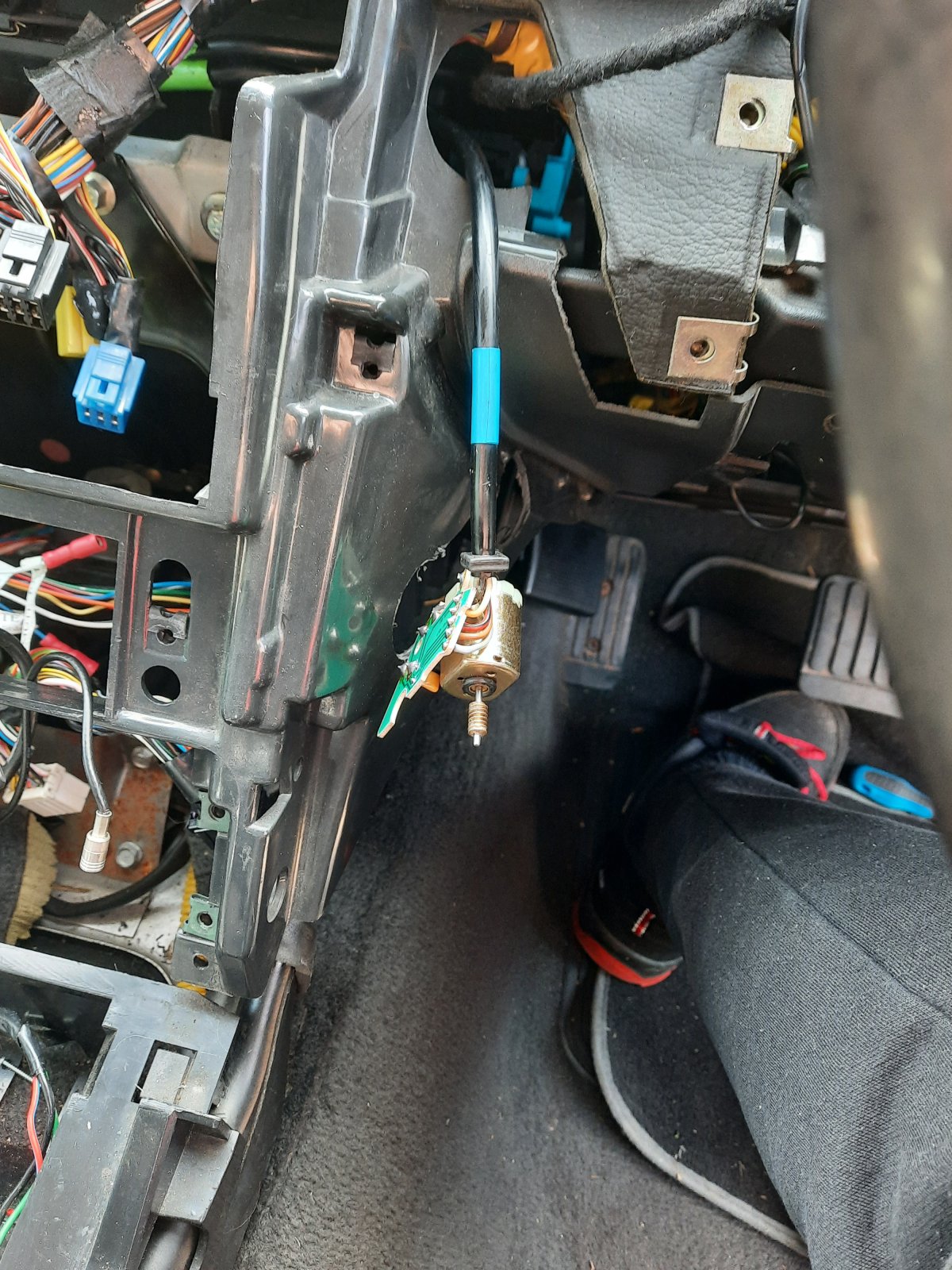

You all may recall I had the book up and nano saying pot fault right hand blend motor? Today, I have tackled the job and soldered in a new pot that I got off kermit_rr, bit of faffing about as the pot drive is 90 deg out but simple once I sussed it.

New pot fitted , note the arrows 90 deg out . Refitted it and that fault has gone according to nano.

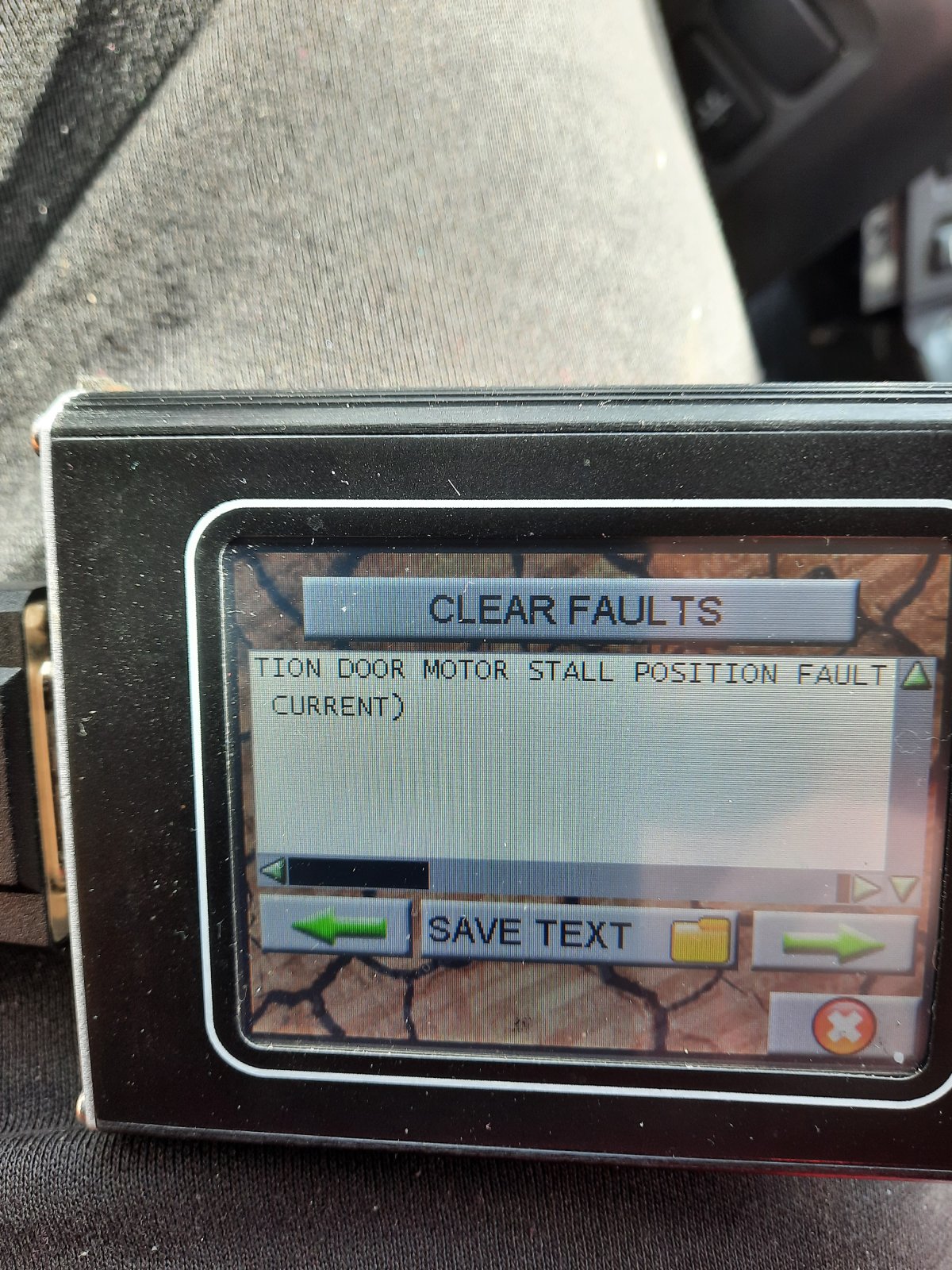

Now, my new fault which won't clear, on the distribution motor.

I've calibrated it twice but the fault won't clear and cycled the ignition 'just incase ', still there and the book also.

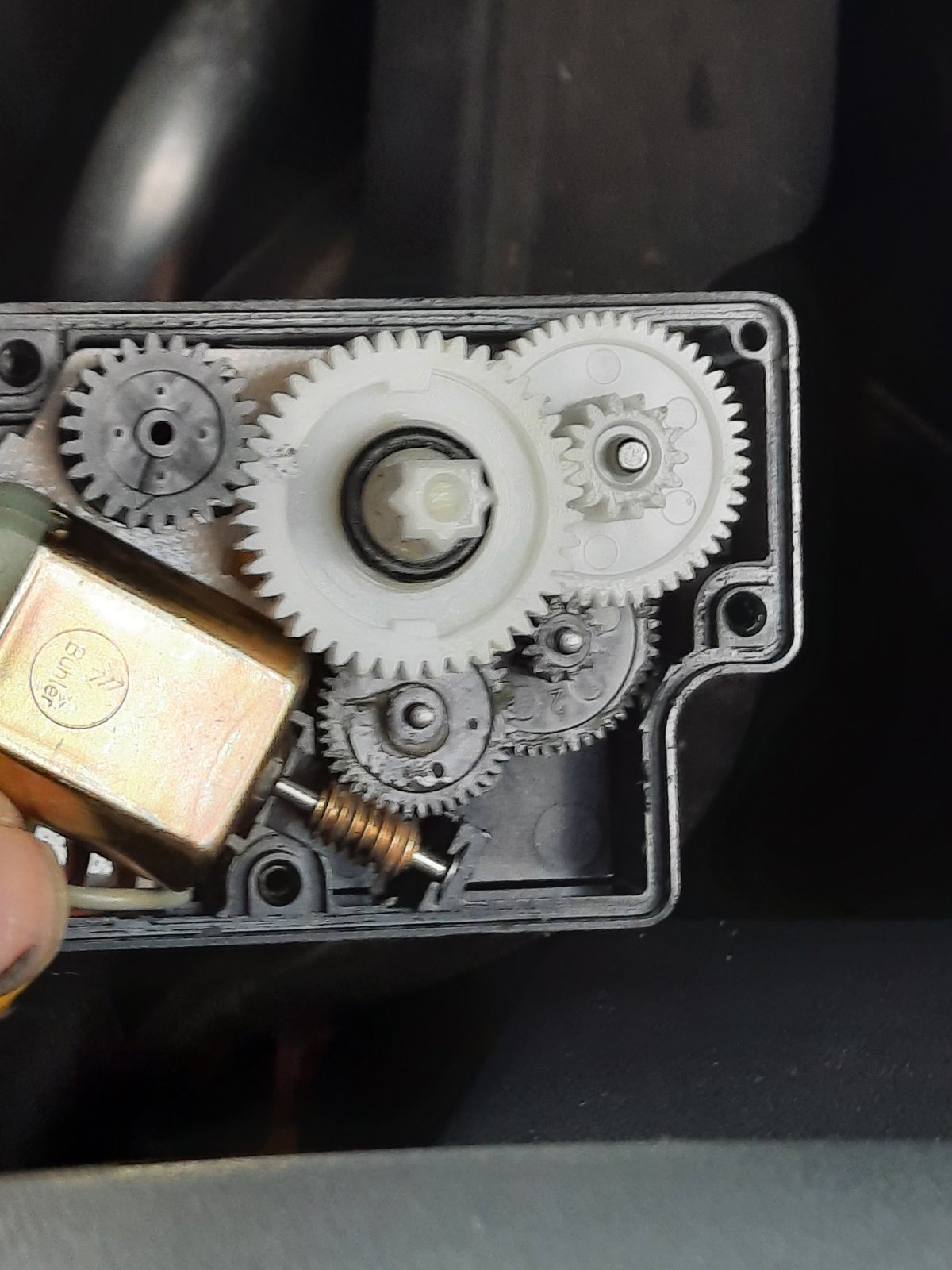

I did take the distribution motor off to check the flap moves easily and also had a peek at the gears inside to check for wear then buttoned it all back up.

When I force the distribution motor with the nano I can see the big white gears moving and the airflow changes as expected so I'm at a bit of a loss now.

New pot fitted , note the arrows 90 deg out . Refitted it and that fault has gone according to nano.

Now, my new fault which won't clear, on the distribution motor.

I've calibrated it twice but the fault won't clear and cycled the ignition 'just incase ', still there and the book also.

I did take the distribution motor off to check the flap moves easily and also had a peek at the gears inside to check for wear then buttoned it all back up.

When I force the distribution motor with the nano I can see the big white gears moving and the airflow changes as expected so I'm at a bit of a loss now.