ciderman

Active Member

- Posts

- 799

- Location

- sunny worcestershire

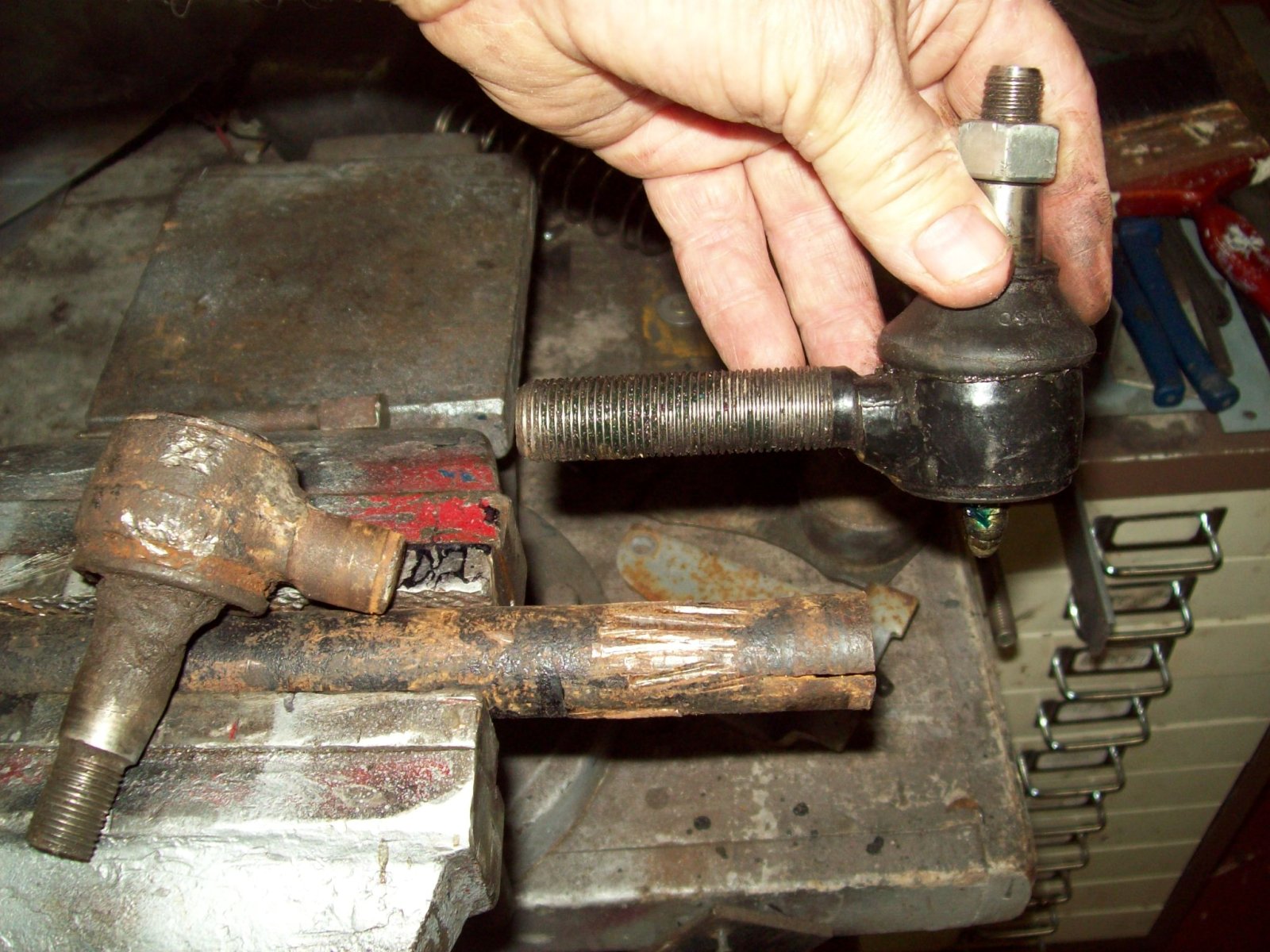

Just a few images of the broken ball joint thread , something i would not have thought possible.

My Very strong young Trainee told me that it must have been faulty. can you see what the cause was? hint 24 inch stilsons involved.

The replacement joints were on the bench at the time, unfortunately I was not supervising..

What words would you use on being told that it was "faulty"

My Very strong young Trainee told me that it must have been faulty. can you see what the cause was? hint 24 inch stilsons involved.

The replacement joints were on the bench at the time, unfortunately I was not supervising..

What words would you use on being told that it was "faulty"