Borja Valls

New Member

- Posts

- 8

Hi everyone, I just traveled from Sydney to Darwin and have started to have lots of issues. Its a long way and there were days that temperature got up to 47 degrees C. First problem was that the old water tank splitted and for the lat 300km i had to stop every 50 and refill. In Darwin I replaced the water tank and sensor and seems ok.

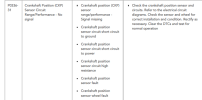

The big issue now is that the car enters in limp mode and lots of system fails after running for 10 minutes. HDC, gear, etc systems all fail and i have to drive slowly and park. I wait 10 minutes and everything works fine again. A mechanic has looked at the trouble code. It seems that he receives the trouble code for crankshaft sensor and other codes after. He has spent hours looking for the sensor. It seems like the position is different depending on the model, year, etc. He has looked everywhere and came back to me saying that It has to be inside the gear box. This means that we would have to remove the gear box to find the sensor inside and change it hoping that it was the one creating the problem. I cant find enough evidence online that the sensor is there and stressed because even if it is, I could not be the original issue. Anyway, I would appreciate if anyone can confirm that the sensor could be in the gear box and whether there are other things to check that could be triggering the limp mode before doing that big job?

The big issue now is that the car enters in limp mode and lots of system fails after running for 10 minutes. HDC, gear, etc systems all fail and i have to drive slowly and park. I wait 10 minutes and everything works fine again. A mechanic has looked at the trouble code. It seems that he receives the trouble code for crankshaft sensor and other codes after. He has spent hours looking for the sensor. It seems like the position is different depending on the model, year, etc. He has looked everywhere and came back to me saying that It has to be inside the gear box. This means that we would have to remove the gear box to find the sensor inside and change it hoping that it was the one creating the problem. I cant find enough evidence online that the sensor is there and stressed because even if it is, I could not be the original issue. Anyway, I would appreciate if anyone can confirm that the sensor could be in the gear box and whether there are other things to check that could be triggering the limp mode before doing that big job?