Not a big update but something worth posting none the less.

I re-checked piston heights.

With this in mind I believe a 3-hole head gasket would be in order.

Some individual cylinder pics just because.

Piston 1:

Piston 2:

Piston 3:

Piston 4:

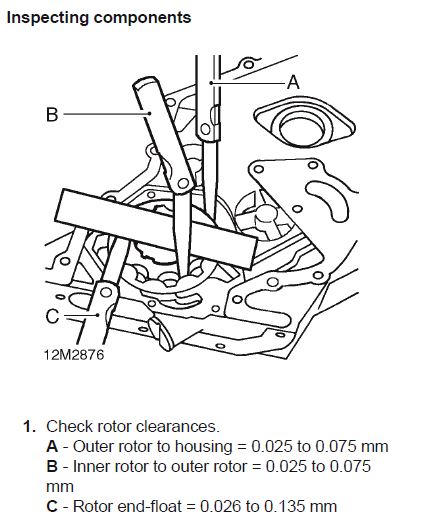

One thing I did manage to do was to figure out the manual in terms of oil pump rotor clearances. I must give my dad credit here as it was his idea to ditch the metric figures and use imperial. using the imperial figures and converting them to metric confirms both the engine overhaul manual as well as the workshop manual to state incorrect metric clearances. The screen grab below shows what is printed in the engine rebuild manual (only metric figures):

I measured the oil pump rotors but my noticed the thinnest finger on my feeler gauge to be 0.05mm which I think is pretty standard. I took measurements anyway and found measurements exceeding the above ten fold. At this point I got a bit worried that I would need to replace the rear timing belt cover in order to correct the clearance of the outer rotor to the housing. Quickly checked the old oil pump and found the measurements also 10x greater than what is printed. Measured the new oil pump and found the same issue. Out came the workshop manual:

My dad noticed the imperial numbers and one of his feeler gauges is marked in both metric and imperial so I rechecked everything using imperial numbers and both the old and new pump is well within limits, obviously the new pump is in a slightly better shape thus I will be fitting the new one.

Using basic maths when converting from metric to imperial where 1 inch = 25.4mm shows that 0.010 in = 0.254mm and not 0.025mm so do not rush out to purchase new parts just yet......first double check the manual

The oil pump cover plate needs a bit of attention. I did not measure the wear as one can clearly feel the ridge with your finger thus it must be in excess of 0.1mm. I will probably get someone to surface grind this for me, failing that I will lap it.

You might ask why the heavy wear on the top of the plate, well the screws holding the plate in place was not properly secured thus the inner rotor was allowed to move or wobble, that is the only explanation I can find. The casing is still in good shape though.