Wagon Loon

Well-Known Member

- Posts

- 573

- Location

- Aberdeen

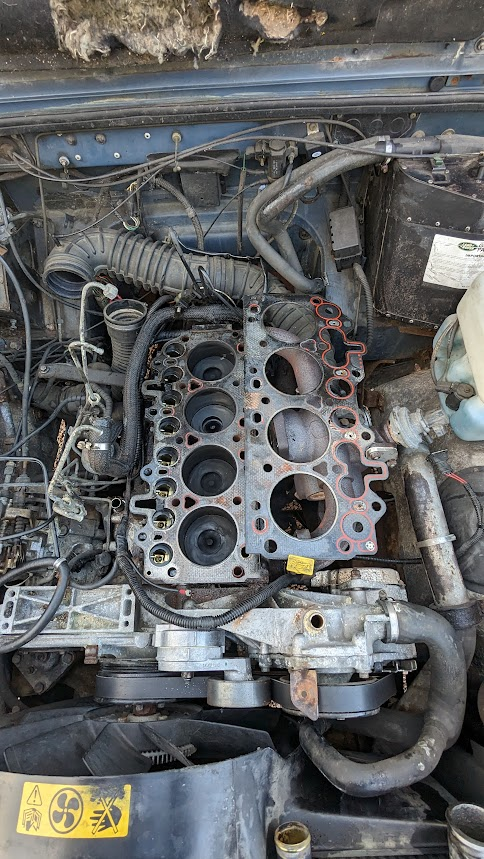

300 tdi I gas flowed my new cylinder head, after head gasket fail, 97 Defender pick-up Peggy

Head gasket on Cyl 3 leaked into water system and had white smoke

Here is a pic of the failed area

Done 140,000, and pic of engine

You may be able to see piston no 3 has been steam cleaned a bit.

I was in the middle of my woodland after a 12 mile drive there, which was a little spirited. However only had Peggy for a few months and rebuilt much of the rear Chassis, installed new standard Flat Dog springs, new bump stops mounts etc. So a recent running and using as a daily driver project.

She was driving beautifully before the gasket went, although I was noticing the need to top up the water very frequently and think the leak was ongoing for some time. My spirited drive just pushed things over!

Having a young woodland is great.

But it takes a lot of time and work. I have a 1974 S3 station wagon Gigi, and she’s been awesome helping me to repair deer fencing and lots of other stuff in the woods. But I got the 300 TDI pick-up to take the load off her because she was built 50 years ago and would like to take it more easy lol

There is quite a lot of work involved , not just sticking another head on, because we're always in such a rush.

I could have just stuck a new gasket in, and it would have been fine, quick and dirty. But a 300tdi doesn't care lol.

However, I’m retired and enjoy having some fun and learning stuff. I am lucky enough to be retired and have Gigi still plus a Subaru XV to which I recently fitted Cooper all terrain tires making quite a capable combination.

I’ve got air tools and bought a dremel tool and air die grinder, and did some indepth research about getting more from my new head.

The factory castings are quite rough through the air passages/Ports, which will obviously cause turbulence, which will reduce air velocity and increase resistance to movement; all of which impedes the free movement of my pistons. Because they have to overcome these resistances and this lost ponies and torque!

But I am no expert, I was never a drip under pressure, as my Dad used to define expert. Just some old guy with a few tools and decades of experience fixing cars.

I will walk through what I've done and briefly explain my reasoning for doing so. I know you can buy a flowed head from Turner engineering, and this would be a really good option. It takes their professionals about ten hours to flow a standard head for you, so a grand for the privilege is of great value. Also, after chatting with them on the phone, they're really helpful and really do know their 300tdi’s.

But I didn't mind working for 50 hours even swirl polishing the backs of my new valves, flowing the leading edge of the exhaust valves and lapping them in with fine 300 grit, then moving into 600 grit for more lapping. It was for fun and a longer term purpose, so just don't take me too seriously, I don't. But I think some folk may be interested to follow my process through and take something from it, like things that are likely not worth the effort or time.

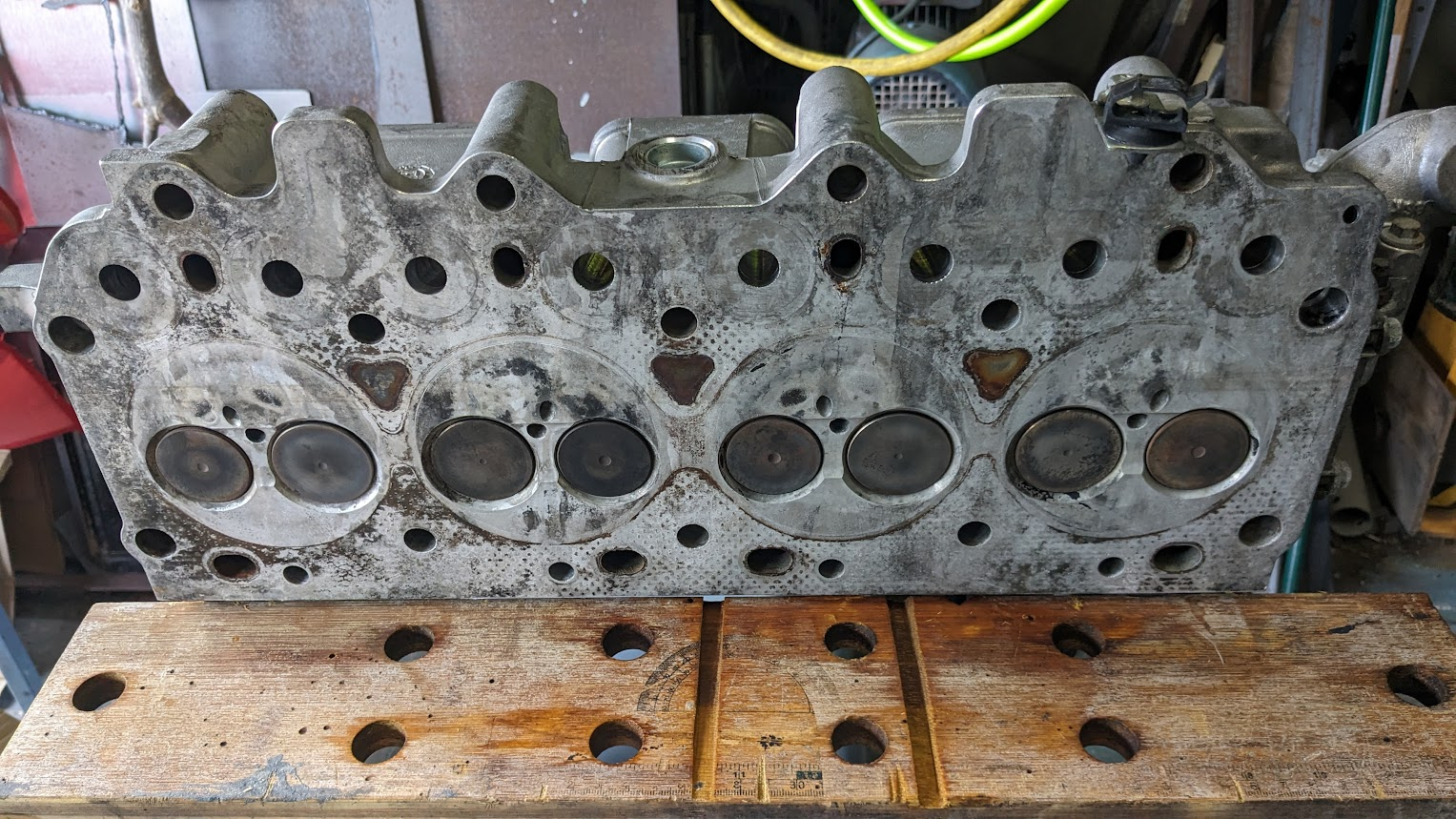

I cleaned up the old head

and sold it on Ebay

I hope it does many more miles. But I wanted to start with new seats and guides etc.

I also cleaned and restored my sump pan, as figured it would tell a story and be full of gungy old oil.

It took a few hours, used two ball pein hammers to resett the bolt holes, cleaned treated rust and painted in 2 pak eurethanol paint for a long lasting tough finish

Followed by removing the pretty shine, because flat black radiates more heat than shiny black.

Head gasket on Cyl 3 leaked into water system and had white smoke

Here is a pic of the failed area

Done 140,000, and pic of engine

You may be able to see piston no 3 has been steam cleaned a bit.

I was in the middle of my woodland after a 12 mile drive there, which was a little spirited. However only had Peggy for a few months and rebuilt much of the rear Chassis, installed new standard Flat Dog springs, new bump stops mounts etc. So a recent running and using as a daily driver project.

She was driving beautifully before the gasket went, although I was noticing the need to top up the water very frequently and think the leak was ongoing for some time. My spirited drive just pushed things over!

Having a young woodland is great.

But it takes a lot of time and work. I have a 1974 S3 station wagon Gigi, and she’s been awesome helping me to repair deer fencing and lots of other stuff in the woods. But I got the 300 TDI pick-up to take the load off her because she was built 50 years ago and would like to take it more easy lol

There is quite a lot of work involved , not just sticking another head on, because we're always in such a rush.

I could have just stuck a new gasket in, and it would have been fine, quick and dirty. But a 300tdi doesn't care lol.

However, I’m retired and enjoy having some fun and learning stuff. I am lucky enough to be retired and have Gigi still plus a Subaru XV to which I recently fitted Cooper all terrain tires making quite a capable combination.

I’ve got air tools and bought a dremel tool and air die grinder, and did some indepth research about getting more from my new head.

The factory castings are quite rough through the air passages/Ports, which will obviously cause turbulence, which will reduce air velocity and increase resistance to movement; all of which impedes the free movement of my pistons. Because they have to overcome these resistances and this lost ponies and torque!

But I am no expert, I was never a drip under pressure, as my Dad used to define expert. Just some old guy with a few tools and decades of experience fixing cars.

I will walk through what I've done and briefly explain my reasoning for doing so. I know you can buy a flowed head from Turner engineering, and this would be a really good option. It takes their professionals about ten hours to flow a standard head for you, so a grand for the privilege is of great value. Also, after chatting with them on the phone, they're really helpful and really do know their 300tdi’s.

But I didn't mind working for 50 hours even swirl polishing the backs of my new valves, flowing the leading edge of the exhaust valves and lapping them in with fine 300 grit, then moving into 600 grit for more lapping. It was for fun and a longer term purpose, so just don't take me too seriously, I don't. But I think some folk may be interested to follow my process through and take something from it, like things that are likely not worth the effort or time.

I cleaned up the old head

and sold it on Ebay

I hope it does many more miles. But I wanted to start with new seats and guides etc.

I also cleaned and restored my sump pan, as figured it would tell a story and be full of gungy old oil.

It took a few hours, used two ball pein hammers to resett the bolt holes, cleaned treated rust and painted in 2 pak eurethanol paint for a long lasting tough finish

Followed by removing the pretty shine, because flat black radiates more heat than shiny black.