pwood999's latest activity

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

-

pwood999 replied to the thread P38 Soft brakes with warning lights.If the same issue on rr.net is also you, as well as reading RAVE, watch the video posted there.

pwood999 replied to the thread P38 Soft brakes with warning lights.If the same issue on rr.net is also you, as well as reading RAVE, watch the video posted there. -

pwood999 replied to the thread What Power Steering Fluid? Millers CHF?.Didn't know it was an FL2 when I posted. Will delete my post !!

pwood999 replied to the thread What Power Steering Fluid? Millers CHF?.Didn't know it was an FL2 when I posted. Will delete my post !! -

pwood999 replied to the thread Power issues.Nanocom shows the boost pressure (I assume MAP), in the EDC-Inputs-General page:

pwood999 replied to the thread Power issues.Nanocom shows the boost pressure (I assume MAP), in the EDC-Inputs-General page: -

pwood999 replied to the thread Classic Hottest weekend of the year - time to fit a Webasto pre-heater!.Remote control ??

pwood999 replied to the thread Classic Hottest weekend of the year - time to fit a Webasto pre-heater!.Remote control ?? -

pwood999 replied to the thread Power issues.+1 on it needing pressure. Just looked at the diagram above, and it's quite obvious when you think about it. The post-turbo intake pipework is unlikely to have much pressure in neutral no matter what revs !! Looking at eBay pics of the...

pwood999 replied to the thread Power issues.+1 on it needing pressure. Just looked at the diagram above, and it's quite obvious when you think about it. The post-turbo intake pipework is unlikely to have much pressure in neutral no matter what revs !! Looking at eBay pics of the... -

pwood999 replied to the thread P38A P38 boot floor welding.I've got a small SIP Migmate 130, but not used it in nearly 20 years !! Problem with it, was the wire feed motor would change speed as the arc started & get stuck. Did a mod using a separate transformer for the feed motor, which worked a...

pwood999 replied to the thread P38A P38 boot floor welding.I've got a small SIP Migmate 130, but not used it in nearly 20 years !! Problem with it, was the wire feed motor would change speed as the arc started & get stuck. Did a mod using a separate transformer for the feed motor, which worked a... -

pwood999 replied to the thread P38A P38 boot floor welding.Doubt it’s that thick. Make it bigger & use a vernier ?? TBH I agree with clean ing rust & use fibreglass & filler.

pwood999 replied to the thread P38A P38 boot floor welding.Doubt it’s that thick. Make it bigger & use a vernier ?? TBH I agree with clean ing rust & use fibreglass & filler. -

pwood999 replied to the thread UJ frustration.When I did my P38 propshafts, the bearing caps were slightly below the circlips. I centred the UJ as best I could, and then filled with grease which expanded the caps firmly against the circlips. Does sound like dropped roller, unless the UJ's...

pwood999 replied to the thread UJ frustration.When I did my P38 propshafts, the bearing caps were slightly below the circlips. I centred the UJ as best I could, and then filled with grease which expanded the caps firmly against the circlips. Does sound like dropped roller, unless the UJ's... -

pwood999 replied to the thread What Power Steering Fluid? Millers CHF?.Content deleted

pwood999 replied to the thread What Power Steering Fluid? Millers CHF?.Content deleted -

pwood999 replied to the thread perfectly working EAS to not rising off bump stops at next start.It’s. It a truck !!

pwood999 replied to the thread perfectly working EAS to not rising off bump stops at next start.It’s. It a truck !! -

pwood999 replied to the thread perfectly working EAS to not rising off bump stops at next start.If the doors & tailgate are all closed, and the car is low, then the compressor is feeding the tank and any airbags that need to rise. To fill the tank only a door or tailgate needs to be open. Your compressor failure two weeks ago could either...

pwood999 replied to the thread perfectly working EAS to not rising off bump stops at next start.If the doors & tailgate are all closed, and the car is low, then the compressor is feeding the tank and any airbags that need to rise. To fill the tank only a door or tailgate needs to be open. Your compressor failure two weeks ago could either... -

pwood999 replied to the thread P38A HEVAC Blend Motor Testing.After doing the chip replacement a while back on my spare HEVAC, got back on the HEVAC in the P38 again today. Replaced the 16-pin connector completely, and then tested all three motors using 9V battery & multimeter. LH Blend pot goes from...

pwood999 replied to the thread P38A HEVAC Blend Motor Testing.After doing the chip replacement a while back on my spare HEVAC, got back on the HEVAC in the P38 again today. Replaced the 16-pin connector completely, and then tested all three motors using 9V battery & multimeter. LH Blend pot goes from... -

pwood999 replied to the thread P38A Oil loss at the engine.Probably the gasket, or whatever sealant has been used in the past. Looks a bit like where the front cover sealant is supposed to go ?? Put the EAS on maximum height, and place blocks under the bump stops to prevent it dropping. Then just...

pwood999 replied to the thread P38A Oil loss at the engine.Probably the gasket, or whatever sealant has been used in the past. Looks a bit like where the front cover sealant is supposed to go ?? Put the EAS on maximum height, and place blocks under the bump stops to prevent it dropping. Then just... -

pwood999 replied to the thread P38A [P38] Common coolant leak locations.+1 ^^^^^^ Release the pressure slowly using a thick towel or rag on the cap.

pwood999 replied to the thread P38A [P38] Common coolant leak locations.+1 ^^^^^^ Release the pressure slowly using a thick towel or rag on the cap. -

pwood999 reacted to Datatek's post in the thread P38A [P38] Common coolant leak locations with

pwood999 reacted to Datatek's post in the thread P38A [P38] Common coolant leak locations withLike.

Careful how you take the cap off the expansion tank because the coolant could boil over. -

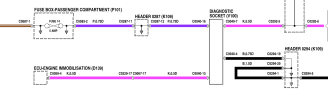

pwood999 replied to the thread Diagnosis based on Symptoms please.It's about right for tickover, but you either need working diagnostics, or move the multimeter so you can see it from drivers seat. For your diagnostic issue, check the voltage across Pin-16 (12V) and Pin-4 (Ground). Connector might need...

pwood999 replied to the thread Diagnosis based on Symptoms please.It's about right for tickover, but you either need working diagnostics, or move the multimeter so you can see it from drivers seat. For your diagnostic issue, check the voltage across Pin-16 (12V) and Pin-4 (Ground). Connector might need... -

pwood999 replied to the thread P0087 Fuel Rail Pressure Too Low.It would help to know the Low & High pressure readings. Might not be the filter

pwood999 replied to the thread P0087 Fuel Rail Pressure Too Low.It would help to know the Low & High pressure readings. Might not be the filter -

pwood999 replied to the thread What have you done to your Freelander today.Took wife's 2005 FL1 for MOT today. Passed with no advisories !!

pwood999 replied to the thread What have you done to your Freelander today.Took wife's 2005 FL1 for MOT today. Passed with no advisories !! -

pwood999 replied to the thread P38A [P38] Common coolant leak locations.Did you do the pressure test wiht the engine hot ? If not, get it properly warmed up for a few miles, and then do the pressure check.

pwood999 replied to the thread P38A [P38] Common coolant leak locations.Did you do the pressure test wiht the engine hot ? If not, get it properly warmed up for a few miles, and then do the pressure check. -

pwood999 replied to the thread Replacing front outer cv boot.You could try the old idea of soaking in bucket of diesel for a week or so ??

pwood999 replied to the thread Replacing front outer cv boot.You could try the old idea of soaking in bucket of diesel for a week or so ?? -

pwood999 replied to the thread P38A [P38] Common coolant leak locations.If it's only a small amount missing, chances are it's evaporated by the time you look for it !!

pwood999 replied to the thread P38A [P38] Common coolant leak locations.If it's only a small amount missing, chances are it's evaporated by the time you look for it !! -

pwood999 replied to the thread P38A MAF woes.Also check that GEMS is set for the correct engine size. 2nd screen in settings menu. Once you get the settings in the right ballpark, you should do some drive cycles to train the ECU.

pwood999 replied to the thread P38A MAF woes.Also check that GEMS is set for the correct engine size. 2nd screen in settings menu. Once you get the settings in the right ballpark, you should do some drive cycles to train the ECU. -

pwood999 replied to the thread What did you do with your Range Rover today.Also unplugged & tested blend & distrib motors using 9V battery & multimeter on the pots via the 16-pin connector. All seem to be working ok with smooth resistance change through the adjustment. But, when plugged back into the HEVAC, I get...

pwood999 replied to the thread What did you do with your Range Rover today.Also unplugged & tested blend & distrib motors using 9V battery & multimeter on the pots via the 16-pin connector. All seem to be working ok with smooth resistance change through the adjustment. But, when plugged back into the HEVAC, I get... -

pwood999 replied to the thread P38A MAF woes.For info, here's my GEMS at idle. No faults stored, and adaptive not cleared for many months.

pwood999 replied to the thread P38A MAF woes.For info, here's my GEMS at idle. No faults stored, and adaptive not cleared for many months. -

pwood999 replied to the thread What did you do with your Range Rover today.Yes, using Nanocom Inputs screen.

pwood999 replied to the thread What did you do with your Range Rover today.Yes, using Nanocom Inputs screen. -

pwood999 reacted to Datatek's post in the thread What did you do with your Range Rover today with

pwood999 reacted to Datatek's post in the thread What did you do with your Range Rover today withLike.

That's HEVAC on diagnostics I presume? The display is outside air temperature. -

pwood999 replied to the thread What did you do with your Range Rover today.Replaced connector on heater core sensor. Old one was rather corroded where the copper wires were crimped. Now HEVAC says correct remp instead of -8deg !!

pwood999 replied to the thread What did you do with your Range Rover today.Replaced connector on heater core sensor. Old one was rather corroded where the copper wires were crimped. Now HEVAC says correct remp instead of -8deg !!