andyfreelandy

Well-Known Member

Been off this for a couple of weeks. Today managed to remove the rear subframe complete with all the bits from the donor. This will be stripped and fitted with the refurbed V6 hubs (old style ABS) and the V6 diff (low mileage).

Not a difficult job once the bolts were loosened. I supported it with wood and jacks on both sides and then slide my faithful flat trolley (made for putting a mini front subframe and engine under a bodyshell!) under the subframe. Only when it was all in place did I remove the last 4 bolts having checked that all handbrake cables and brake pipes were disconnected. Fiddly bit is disengaging the exhaust pipe from the Chinese puzzle link through the rear driveshafts and bars !

Although I managed to remove the bolts holding the subframe, the bolts and nuts holding the hubs and links are well past their best and will need to be cut off.

Two questions please:

1) - What is the best way to get off a completely seized nut and bolt - angle grinder, hacksaw, heat, nut splitter?? I have loads to do and would appreciate experience of others.

2) - Does anyone know where all the nuts and bolts and the very long hub pivot bolt can be obtained from (apart from dealer!) - is there a kit, if so I would appreciate ordering details.

Will put some photos up of the removed frame. Diff from the TD4 donor is in excellent condition, it is going on my car to remove the 'overrun whine' that I get on motorways.

Not a difficult job once the bolts were loosened. I supported it with wood and jacks on both sides and then slide my faithful flat trolley (made for putting a mini front subframe and engine under a bodyshell!) under the subframe. Only when it was all in place did I remove the last 4 bolts having checked that all handbrake cables and brake pipes were disconnected. Fiddly bit is disengaging the exhaust pipe from the Chinese puzzle link through the rear driveshafts and bars !

Although I managed to remove the bolts holding the subframe, the bolts and nuts holding the hubs and links are well past their best and will need to be cut off.

Two questions please:

1) - What is the best way to get off a completely seized nut and bolt - angle grinder, hacksaw, heat, nut splitter?? I have loads to do and would appreciate experience of others.

2) - Does anyone know where all the nuts and bolts and the very long hub pivot bolt can be obtained from (apart from dealer!) - is there a kit, if so I would appreciate ordering details.

Will put some photos up of the removed frame. Diff from the TD4 donor is in excellent condition, it is going on my car to remove the 'overrun whine' that I get on motorways.

andyfreelandy

Well-Known Member

oh - forgot to mention that both front brakes and suspension are now complete. With regards to tightening the front hub nut - my impact driver has a torque of about 300 ft/lb. If I apply this until the nut no longer turns will this be adequate? Book says 295 ft/lb !

blodge

Member

1) There is no magic tool or potion that will work every time to release a seized bolt - a well balanced hammer (with the room to swing it), a set of long punches, a fine flame propane torch and a can of Plus Gas will get you a long way once the nut has been cut off. I have never had a lot of luck with nut splitters and there never seems to be room for a hacksaw on most modern cars so angle-grinder if you have room for it or I like the Dremel and the SpeedClic cutting discs for getting the awkward ones off. Drilling down the centre of a stuck bolt will also often de-stress it enough to get the thing to turn.1) - What is the best way to get off a completely seized nut and bolt - angle grinder, hacksaw, heat, nut splitter?? I have loads to do and would appreciate experience of others.

2) - Does anyone know where all the nuts and bolts and the very long hub pivot bolt can be obtained from (apart from dealer!) - is there a kit, if so I would appreciate ordering details.

.

2) I couldn't find a kit of bolts and had to track down all of the part numbers individually but I would love to hear if someone has a kit - I am sure there will be a next time! I purchased most of the bits from LRDirect and had the rest in my parts box.

andyfreelandy

Well-Known Member

Ordered bolts and nuts from local LR dealer at similar prices to making many different orders as there seems no one that stocks all the bits !

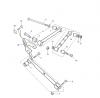

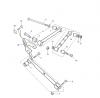

Surprisingly the strut to hub bolts are, according to LR dealer, 'obsolete' - which is a surprise - found them at LR direct as you suggested. My local dealer sent me this useful diagram.

Surprisingly the strut to hub bolts are, according to LR dealer, 'obsolete' - which is a surprise - found them at LR direct as you suggested. My local dealer sent me this useful diagram.

andyfreelandy

Well-Known Member

Most are giving way to heat. There have, however, been several executions with the grinder. Glad I have replacements for all!!

andyfreelandy

Well-Known Member

All donor rear subframe now completely stripped ready for sandblast and paint. Also took off fuel tank support to clean and reuse. This will need the plates replacing with chequer plate. Now to the V6. Hoping hubs will come off as I need to reuse these and shafts. Remainder is scrap except diff. Has anyone changed a reluctance ring type ABS to magnetic type? Wondered if you could change shafts, hubs, sensors and ABS modulator with ecu?!?! Simples.......

andyfreelandy

Well-Known Member

Not an easy job - more like demolition than motor engineering !

Started to strip the V6 subframe before removal - need hubs, diff and driveshafts. One hub off - one to go !

Some removal techniques and bolts with a bit of rust !

Rather worrying was the handbrake cable mount on the rear backplate with daylight around it ! It just pulled out with a bit of rusty plate attached to it.

Rather worrying was the handbrake cable mount on the rear backplate with daylight around it ! It just pulled out with a bit of rusty plate attached to it.

Ending up with a pile of bits to refurb - subframe and all arms are scrap. Diff and driveshafts will be lifted off when subframe out and transplanted onto refurbed subframe with new mounts.

Will then fit subframe and build up with clean / new parts as required.

One more hub to remove and then I think the muscles might get a rest !

Pile of scrap continues to increase.......................

Started to strip the V6 subframe before removal - need hubs, diff and driveshafts. One hub off - one to go !

Some removal techniques and bolts with a bit of rust !

Rather worrying was the handbrake cable mount on the rear backplate with daylight around it ! It just pulled out with a bit of rusty plate attached to it.

Rather worrying was the handbrake cable mount on the rear backplate with daylight around it ! It just pulled out with a bit of rusty plate attached to it.Ending up with a pile of bits to refurb - subframe and all arms are scrap. Diff and driveshafts will be lifted off when subframe out and transplanted onto refurbed subframe with new mounts.

Will then fit subframe and build up with clean / new parts as required.

One more hub to remove and then I think the muscles might get a rest !

Pile of scrap continues to increase.......................

andyfreelandy

Well-Known Member

Back on the case after a break (mostly fault finding the TD4!).

Today removed all of the V6 rear subframe. Started to strip it on the car, but the going (and rust) was tough and so I decided to remove the entire subframe. Disconnected the propshaft, disconnected the exhaust front joint, removed the two trailing links and then four bolts and trolleyed the whole assembly out from under the car.

Exhaust is savable, this cost the PO £620 3 years ago. Only things that are required are the diff, two driveshafts and the hubs. I need these as this car has the earlier 'black plug' ABS and the reluctance rings fitted to the driveshafts. I am not sure that the hubs can be saved yet, it depends on my ability to drive out or drill out the long bolt that runs through the lower section without damaging them.

Now that the rusty stuff is off, the underside looks quite good. I will be wire brushing and paining before refitting the refurbed rear subframe assembly and I am planning to rebuild it as per the photo above, that is with the chinese puzzle exhaust fed in through the rear suspension. Not easy to fit afterwards with the car on the ground !

I also think the rear struts are too far gone and shall be refurbing the ones from the donor car and fitting the springs from the V6.

Underside not bad at all - subframe being a separate unit is good design (no not good design on a Land Rover surely !) - the four bolts unscrewed fairly easily after a few weeks with penetrating oil being sprayed onto the threads via the conveniently placed plugs in the boot floor ! Loosening a few turns, spraying, leaving and then tightening a few times reduces the risk of breaking off the captive nuts in the body box section - and a lengthy repair !

Underside not bad at all - subframe being a separate unit is good design (no not good design on a Land Rover surely !) - the four bolts unscrewed fairly easily after a few weeks with penetrating oil being sprayed onto the threads via the conveniently placed plugs in the boot floor ! Loosening a few turns, spraying, leaving and then tightening a few times reduces the risk of breaking off the captive nuts in the body box section - and a lengthy repair !

Will strip off what I need and refurb then reassemble ready to fit - I may be a few weeks..........................

Today removed all of the V6 rear subframe. Started to strip it on the car, but the going (and rust) was tough and so I decided to remove the entire subframe. Disconnected the propshaft, disconnected the exhaust front joint, removed the two trailing links and then four bolts and trolleyed the whole assembly out from under the car.

Exhaust is savable, this cost the PO £620 3 years ago. Only things that are required are the diff, two driveshafts and the hubs. I need these as this car has the earlier 'black plug' ABS and the reluctance rings fitted to the driveshafts. I am not sure that the hubs can be saved yet, it depends on my ability to drive out or drill out the long bolt that runs through the lower section without damaging them.

Now that the rusty stuff is off, the underside looks quite good. I will be wire brushing and paining before refitting the refurbed rear subframe assembly and I am planning to rebuild it as per the photo above, that is with the chinese puzzle exhaust fed in through the rear suspension. Not easy to fit afterwards with the car on the ground !

I also think the rear struts are too far gone and shall be refurbing the ones from the donor car and fitting the springs from the V6.

Underside not bad at all - subframe being a separate unit is good design (no not good design on a Land Rover surely !) - the four bolts unscrewed fairly easily after a few weeks with penetrating oil being sprayed onto the threads via the conveniently placed plugs in the boot floor ! Loosening a few turns, spraying, leaving and then tightening a few times reduces the risk of breaking off the captive nuts in the body box section - and a lengthy repair !

Underside not bad at all - subframe being a separate unit is good design (no not good design on a Land Rover surely !) - the four bolts unscrewed fairly easily after a few weeks with penetrating oil being sprayed onto the threads via the conveniently placed plugs in the boot floor ! Loosening a few turns, spraying, leaving and then tightening a few times reduces the risk of breaking off the captive nuts in the body box section - and a lengthy repair !Will strip off what I need and refurb then reassemble ready to fit - I may be a few weeks..........................

andyfreelandy

Well-Known Member

So rusty - rattled the heads off !

Alibro

Well-Known Member

LOL, I think that may have happened to me too. If I recall I used a welder to heat the bolt up before bashing it out but I had to cut a chunk out of the middle so I was pushing it through one hole at a time.So rusty - rattled the heads off !

andyfreelandy

Well-Known Member

Good decision on the 'change the struts' plan !

Stickers have lasted longer than the metal !

Stickers have lasted longer than the metal !

Handbrake cable mount fell away on contact !

Handbrake cable mount fell away on contact !

Scrap remaining after taking all that is good for refurb.

Scrap remaining after taking all that is good for refurb.

Can't shift the long bolts in the hub. I have cut them off and cut out the centre section, heated, lubricated, welted all to no avail. Now have ground ends flat and using trusty pillar drill to gently drill out the old material taking care not to enlarge or elongate the holes. I am hoping once I get 90% there the remaining 'tube' will rotate and fall out - we can dream. Diff oil was lovely and clean, slightly dark.

Next job is to clean up the hubs, remove the bolt stubs (see above) and then pack off a load to the sandblaster.

Haven't used my spring compressors since replacing the Macpherson struts on my 100E Ford Prefect !

Springs were smaller then - could only get 3 coils - but it did the trick, never underestimate the power of a compressed vehicle spring.

Springs were smaller then - could only get 3 coils - but it did the trick, never underestimate the power of a compressed vehicle spring.

Stickers have lasted longer than the metal !

Stickers have lasted longer than the metal ! Handbrake cable mount fell away on contact !

Handbrake cable mount fell away on contact ! Scrap remaining after taking all that is good for refurb.

Scrap remaining after taking all that is good for refurb.Can't shift the long bolts in the hub. I have cut them off and cut out the centre section, heated, lubricated, welted all to no avail. Now have ground ends flat and using trusty pillar drill to gently drill out the old material taking care not to enlarge or elongate the holes. I am hoping once I get 90% there the remaining 'tube' will rotate and fall out - we can dream. Diff oil was lovely and clean, slightly dark.

Next job is to clean up the hubs, remove the bolt stubs (see above) and then pack off a load to the sandblaster.

Haven't used my spring compressors since replacing the Macpherson struts on my 100E Ford Prefect !

Springs were smaller then - could only get 3 coils - but it did the trick, never underestimate the power of a compressed vehicle spring.

Springs were smaller then - could only get 3 coils - but it did the trick, never underestimate the power of a compressed vehicle spring.andyfreelandy

Well-Known Member

You would think so - it lived on a hill about 1/2 mile from coast in Somerset. It is fortunate to get all this work done to it, it was destined for the scrappy and I must admit it made me go 'wtf' when I looked underneath, but it was cheap, low mileage, V6, ES and when you unbolt all the rusty stuff it really isn't too bad. It has also given me an opportunity to do work 'other than engines' - but it is harder work. All rear end now sprayed with rust neutraliser then will wire brush and paint. No holes in chassis - yet !

andyfreelandy

Well-Known Member

Today cleaned up hubs and removed old bearings - bit ropey so it made it easier to clean with them out. Also, managed to remove the long bolts from the hub. Thanks for tips received, cut off nut and bolt head, cut out centre section and leave just 2 short stubs in the hub itself. Then centre punch (but just off centre) and drill pilot hole. Increase drill size until you just break the edge of the rusted stub - see. Don't drill right through. Insert punch and knock the stub out. It worked on all 4 !

Used disc cutter to remove rusted fuel tank support brackets and made up two new ones using checker plate. New plates will be drilled down the centre and fixed to the frame using countersunk screws. Frame will be drilled and tapped to suit. Collated all useable material to go for blasting.

Yes, it is the same hub ! Ready for rust killer and paint. Very careful with ABS sensor - too tight to replace them !

Yes, it is the same hub ! Ready for rust killer and paint. Very careful with ABS sensor - too tight to replace them !

Stub of remainder of long bolt drilled (off centre till it breaks out) then drifted out with punch.

Stub of remainder of long bolt drilled (off centre till it breaks out) then drifted out with punch.

Replacement fuel tank support plates. Frame was actually ok and cleaned up fine. Folded over a scaffold pole, the required bends are at an angle to the plate and so my design has a left and right 'lean' which will fit o.k.

Replacement fuel tank support plates. Frame was actually ok and cleaned up fine. Folded over a scaffold pole, the required bends are at an angle to the plate and so my design has a left and right 'lean' which will fit o.k.

To be sandblasted and epoxy coated prior to reassembly.

To be sandblasted and epoxy coated prior to reassembly.

So far, the only items replaced are the adjustable tie bars (no thread left on them!) and the checker plate - about £40 in all.

Next installment is the refurbished bits being fitted back together - will be measuring the old tie bars very accurately and setting the new ones to the same setting before taking vehicle for 4 wheel alignment.

Used disc cutter to remove rusted fuel tank support brackets and made up two new ones using checker plate. New plates will be drilled down the centre and fixed to the frame using countersunk screws. Frame will be drilled and tapped to suit. Collated all useable material to go for blasting.

Yes, it is the same hub ! Ready for rust killer and paint. Very careful with ABS sensor - too tight to replace them !

Yes, it is the same hub ! Ready for rust killer and paint. Very careful with ABS sensor - too tight to replace them ! Stub of remainder of long bolt drilled (off centre till it breaks out) then drifted out with punch.

Stub of remainder of long bolt drilled (off centre till it breaks out) then drifted out with punch. Replacement fuel tank support plates. Frame was actually ok and cleaned up fine. Folded over a scaffold pole, the required bends are at an angle to the plate and so my design has a left and right 'lean' which will fit o.k.

Replacement fuel tank support plates. Frame was actually ok and cleaned up fine. Folded over a scaffold pole, the required bends are at an angle to the plate and so my design has a left and right 'lean' which will fit o.k. To be sandblasted and epoxy coated prior to reassembly.

To be sandblasted and epoxy coated prior to reassembly. So far, the only items replaced are the adjustable tie bars (no thread left on them!) and the checker plate - about £40 in all.

Next installment is the refurbished bits being fitted back together - will be measuring the old tie bars very accurately and setting the new ones to the same setting before taking vehicle for 4 wheel alignment.

andyfreelandy

Well-Known Member

Whilst waiting for Santa to return the blasted and coated suspension bits, I finished refurbing a hub, put in a new wheel bearing, repainted the fuel tank frame and fitted the new checker plate guards (they won't go rusty!). Cleaned up brake shoes and bits ready to refit - photos taken to show where springs and adjusters go.

Hub, rust killer, wire brush, Hammerite and new bearings.

Hub, rust killer, wire brush, Hammerite and new bearings.

Rusted out fuel tank support cleaned up, Hammerited and new supports made out of 2mm checker plate.

Rusted out fuel tank support cleaned up, Hammerited and new supports made out of 2mm checker plate.

Brake assembly - other side is mirror image. And closer up for reference:

Brake assembly - other side is mirror image. And closer up for reference:

That'll do for now - let's hope that a rear subframe fits inside a stocking

Hub, rust killer, wire brush, Hammerite and new bearings.

Hub, rust killer, wire brush, Hammerite and new bearings. Rusted out fuel tank support cleaned up, Hammerited and new supports made out of 2mm checker plate.

Rusted out fuel tank support cleaned up, Hammerited and new supports made out of 2mm checker plate. Brake assembly - other side is mirror image. And closer up for reference:

Brake assembly - other side is mirror image. And closer up for reference:

That'll do for now - let's hope that a rear subframe fits inside a stocking

andyfreelandy

Well-Known Member

Indeed I have. Changed all those on the daily fleet too. Too scary to ignore for £2! My fuel tank cradle cost me £5.20 for two offcuts of ali ! Thanks for feedback.