Well Its Saturday Evening and you all know what that means - - Yes its Photo Time

Today I needed to start finishing off some small bits as I head towards completion of the GreenHornet, not that completion is an option as there is always something for a LR owner to do

Mostly this hinges around putting the thing back together after bits have either fallen off or been ripped off.

Anyway the first thing on thelist was the Sedementor. Now I have read many posts arguing the need for this piece of equipment and to some extent I am on the side of Joe Blogs whose arguement is that if its too hard to service and maintain and give little perceived benefit - then rip the ****er out

However on opening mine up I will be doing a Cameron and performing a complete U Turn.

The sedementor for the benefit of those that dont know, is mounted on the offside rear of the vehicle just in front of the axle. Well in front of the axle if you think the front of the car is where the front is, however if you are stood behind the vehicle you may feel, no matter how incorrectly that the front of the axle is in front of you. I know that the front is actually in fact in front of your but you could argue that the rear of the axles is also in froint of you too. Anyway for the purposes of clarity, the front of the axle is where the prop shaft fits into the differential - :doh:

So the Sedementor was already unbolted as I had replaced the suspension and all I did was to remove the bolt at the top of it which is located in the centre.

Be careful of the rubber O-Ring to the bowl. Now remove the bowl and boy it was full of ****. Sand, Fat as I run veggie from time to time and some rather black tar looking stuff too. Anyhow it was all stuff that I wouldn't want to block my fuel pipe so I will be keeping it.

The underside of the top section of the item houses the seperator which I imagine helps skim the crap off the top and therefore only allows descent clean fuel through.

A good clean all orund and inside and also I made sure that the plastic drain plug was taken out. I cleaned the threads and put it back in finger tight as the next time I will be servicing this item will be from underneath and you dont want to be struggling as room can be tight.

Yeah

Up there for thinking and down there for dancing...

So it was all bolted together and then mounted on the frame by the chassis. I made sure that the bolts were tight but not too tight that they couldn't be undone whilst underneath.

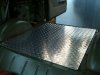

Then I made sure the new boot floor would fit. I bought some 2mm Chequer plate off fleabay for £47. The measurements are 1250mm x 1000mm and it fitted perfectly. Looks the dogs danglys - well not my dog as we had him done last year. Poor sod but in our defence i did actually catch him humping my 5 year old son so that was the key decision maker - I mean the dog scratched all his sides and was shoving him around the living room....

Finally I put the wheels back on so I could take a descent photo of how she looks.

I then had a quick look at the rear springs. A friend said that the rear springs were seated incorrectly so I unbolted the base and twisted them around until they appeared to seat properly. I think they are OK but the tail of the spring doesnt face me which is what my friend said should be the case. Anyhow I will be testing the articulation set up once the rest is done so will do final adjusting then.

Finally I fitted a wading kit. I fitted new hoses and banjos to the front and rear axles and also a vent to the timing cover. However there are supposed to be vents to the transfer box and the gearbox but I cant find them - can anyone help????

So what do we think of the 300 style front end?? I prefer the 200 front end but didnt have a choice cause of the panels but I like it all the same.

Now tomorrow we will be fitting the inner wing bits and bobs such as air cleaner and header tank etc and then the interior will be going in. I have the battery on charge so cant wait to fire her up again.