ReadySalted

Active Member

- Posts

- 444

Hi,

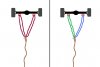

I was on the OLLR forum today just nosing around and looking at their members photos, and came across this pic:

Now, I do a bit of climbing, (as in rock), and one of the first things you learn when setting up an anchor for climbing, is never to use that method. It's known as the american triangle, and I've heard people call it 'death triangle'.

The reason is because by having the two anchors (around each of his leaf spring shackles by the look of it), it puts more strain on each of the anchors (i.e. his leaf spring shackles).

I've seen 4x4 owners use it before and just wondered why it's commonplace in the 4x4 world, when it seems almost forbidden in the climbing community.

I know that 4x4s are alot stronger than pitons and climbing gear, but it's still effectively doubling the strain by using two anchors in this way.

I was on the OLLR forum today just nosing around and looking at their members photos, and came across this pic:

Now, I do a bit of climbing, (as in rock), and one of the first things you learn when setting up an anchor for climbing, is never to use that method. It's known as the american triangle, and I've heard people call it 'death triangle'.

The reason is because by having the two anchors (around each of his leaf spring shackles by the look of it), it puts more strain on each of the anchors (i.e. his leaf spring shackles).

I've seen 4x4 owners use it before and just wondered why it's commonplace in the 4x4 world, when it seems almost forbidden in the climbing community.

I know that 4x4s are alot stronger than pitons and climbing gear, but it's still effectively doubling the strain by using two anchors in this way.