Bit different today. Too hot to be spannering so just cleaning up house/tools etc. Decided to do the headliner

Drying off in the sun.

I now have to decide between nutmeg white, Jasmine white, natural calico etc.

I actually wouldn't mind it being a sandy colour... hmmm

Drying off in the sun.

I now have to decide between nutmeg white, Jasmine white, natural calico etc.

I actually wouldn't mind it being a sandy colour... hmmm

You could always use a 20mm foam backing and a quilted faux leather with some tufting dimples in it, very retro 70s lol

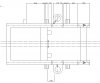

Did some measuring up tonight for my own self assurance.

I'll update it as I go and we will end up with a full chassis drawing. Not sure If I'll be able to do a side profile accurately but the below near enough gives me what I require for repair. I'll also do a rear cross member drawing for the tank cradle bracket as I need to fab one up. Believe it or not LR seem to have made it all in whole numbers..... Thank F.....

I'll update it as I go and we will end up with a full chassis drawing. Not sure If I'll be able to do a side profile accurately but the below near enough gives me what I require for repair. I'll also do a rear cross member drawing for the tank cradle bracket as I need to fab one up. Believe it or not LR seem to have made it all in whole numbers..... Thank F.....

Attachments

Last edited:

Did some measuring up tonight for my own self assurance.

I'll update it as I go and we will end up with a full chassis drawing. Not sure If I'll be able to do a side profile accurately but the below near enough gives me what I require for repair. I'll also do a rear cross member drawing for the tank cradle bracket as I need to fab one up. Believe it or not LR seem to have made it all in whole numbers..... Thank F.....

Nice, I'll keep scribling on the back of fag packet, I've advanced from drawing on my hands LOLZ

Fraid that means nothing to me

*feels inadequate*

Chris all it is is the measurements between your boot supports and spring seat. I need to chop both out on one side. As you know the spring seat is angled. the lines through the chassis on the spring sheet illustrate the bottom of flange and top. its just a draft at the moment and I'm sure the cross member measurement is out on it. I need to double check.

When I put a bit more to it I will put notes all over it and all will become clear.

I haven't touched 3d stuff for some time but plan top make myself competent in it again and will do the disco chassis. I'm not a mechanical engineer by trade but can put together most simple things provided I have the measurements - let me know if you want anything CAD'ing up.

Nice, I'll keep scribling on the back of fag packet, I've advanced from drawing on my hands LOLZ

I wasn't getting a 200 sleeve just to fit the chassis on. This one's for you then lol

I wasn't getting a 200 sleeve just to fit the chassis on. This one's for you then lol

View attachment 155212

Great, makes me feel betterer, I spent the last few days on a GPS equipped 360 where I'm working to create a topographical masterpiece (read as "wondering exactly what the engineer was smoking when he programmed the coordinates into the file logger") and it's been a ball ache trying to follow the plan, I often prefer old school engineering pins so I can visualise what I'm doing.

How is the planning so far? You must be nearly finished the drivers side rear end and getting ready for the rear cross member then on to the passenger side rear end?

Great, makes me feel betterer, I spent the last few days on a GPS equipped 360 where I'm working to create a topographical masterpiece (read as "wondering exactly what the engineer was smoking when he programmed the coordinates into the file logger") and it's been a ball ache trying to follow the plan, I often prefer old school engineering pins so I can visualise what I'm doing.

How is the planning so far? You must be nearly finished the drivers side rear end and getting ready for the rear cross member then on to the passenger side rear end?

Can't beat pins mate. Was your 360 running a Trimble? They hook graders and pavers up them now. Site set out now is walking around with a pogo stick on GPS and just logging points. Staff and theodolite are old hat now i guess. I remember everything being set from bench marks and you had to calc from that.

Yes drivers side done apart from arch which I've been told to do once I have boot floor. Next job is chop rear cross member and fab up new cradle bracket. I then have to do those nasty bits on chassis i.e. spring seat.

Can't beat pins mate. Was your 360 running a Trimble? They hook graders and pavers up them now. Site set out now is walking around with a pogo stick on GPS and just logging points. Staff and theodolite are old hat now i guess. I remember everything being set from bench marks and you had to calc from that.

Yes drivers side done apart from arch which I've been told to do once I have boot floor. Next job is chop rear cross member and fab up new cradle bracket. I then have to do those nasty bits on chassis i.e. spring seat.

We are running a Leica iCON machine control with full 3D mapping and graphics, very cool, 15 years ago we had the early Trimble gear on a Volvo EC290 on the A130 at Rettondon Turnpike, it was very cutting edge and I knew it was the future back then but it was far too expensive to even be considered on more than just a couple of the special machines that were on slow labour intensive grading of type 1 formation, it made that much much faster and made it far more profitable!

This is the one I've been using this week.

Might have to head off to another job next week as the guy who's machine I've been driving these last days will be back and my machine is currently broke down, or I might stay here on his machine as he doesn't like the GPS all that much and especially not on this type of work as it kind of wrecks your head a little in the beginning until you start to form the shape a little it isn't exactly obvious as to what you are creating.

Chassis will come good quite quick and I recon that you will find it easier when you have a few full days at it on your holidays.

Holy **** that tech has come a long way. Trimble was first one I saw about 8 year ago in a paving gang lol.

Had some sad news this weekend. An old friend taken too early. Was away fishing on Friday night and Saturday. Worked on disco this afternoon. Just like fishing it it helped with keeping me busy and out.

Here's the intimidating repair. @dieseldog69 is the nut under the a frame ball a 32? Couldn't get a 32 over it due to lack of room so guess I need a 32 spanner?

Had some sad news this weekend. An old friend taken too early. Was away fishing on Friday night and Saturday. Worked on disco this afternoon. Just like fishing it it helped with keeping me busy and out.

Here's the intimidating repair. @dieseldog69 is the nut under the a frame ball a 32? Couldn't get a 32 over it due to lack of room so guess I need a 32 spanner?

Chrisw8

Well-Known Member

Got mine to do too .

Got a 32mm spanner from when I changed the heat exchanger on boiler.

It was urgent need, so got it from Halfords (professional range) about 11quid if memory serves.

I bought a complete unit with the ball joint already fitted.

Keep posting how you get on.

I have been looking on YRM site at A4-80 s/s fitting kits for all the suspension parts. They seem quite good value compared to trying to source on web. ..... though when you see the shopping cart getting fuller ....

Got a 32mm spanner from when I changed the heat exchanger on boiler.

It was urgent need, so got it from Halfords (professional range) about 11quid if memory serves.

I bought a complete unit with the ball joint already fitted.

Keep posting how you get on.

I have been looking on YRM site at A4-80 s/s fitting kits for all the suspension parts. They seem quite good value compared to trying to source on web. ..... though when you see the shopping cart getting fuller ....