Hi all,

First post here, so thanking everyone in advance for any help.

I'm tearing my hair out with a TD5 Disco 2 Auto we use at our sailing club for shunting round trailers.

Out of the blue the two flashing green transmission lights appeared on the dashboard and the gearbox went into limp mode. At the same time the front windows stopped working.

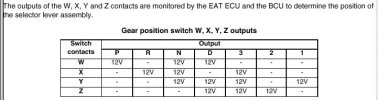

Nanocom threw up a P0705 Position sensor error.

Clearing the fault, resulted in it immediately returning.

So far we have :

Swapped the good XYZ sensor from our other Disco 2. It made no difference. The one off the faulty Disco, worked perfectly on the good donor Disco so we have ruled out the sensor itself.

Checked the wiring loom on top of the gearbox for any chafing, which there isn't and also checked for continuity on all the wires from the XYZ sensor and the other transmission wires running through the loom back to the connector blocks under the centre console. All have good continuity.

Swapped the gearbox ECU off the good Disco onto the poorly one. It made no difference and the one off the poorly one works fine on the good one.

When trying both front front windows there are no relay clicking sounds coming from the BCU module. Both windows worked correctly before the green flashing transmission warning lights appeared.

Checked the battery voltage and ran a direct earth from the battery to the BCU and gearbox loom earthing points. Made no difference.

Could it be a faulty BCU or damage to the wiring somewhere between the centre console and the passenger footwell where the BCU is located?

Any other ideas?

Is it possible to swap out the BCU on a plug and play basis with a known fully functional one or would we need to use Nanocom to configure it? Thinking we could try the BCU off the working Disco.

The fact that the front windows are controlled by the BCU and also the XYX sensor is linked to the BCU makes me think the gearbox and electric window faults are not coincidental and must be related.

I've googled the topic to death and can't find any info on a combination of P0705 fault codes and dead front electric windows.

Any pointers would be much appreciated!!!!!!

Thanks

First post here, so thanking everyone in advance for any help.

I'm tearing my hair out with a TD5 Disco 2 Auto we use at our sailing club for shunting round trailers.

Out of the blue the two flashing green transmission lights appeared on the dashboard and the gearbox went into limp mode. At the same time the front windows stopped working.

Nanocom threw up a P0705 Position sensor error.

Clearing the fault, resulted in it immediately returning.

So far we have :

Swapped the good XYZ sensor from our other Disco 2. It made no difference. The one off the faulty Disco, worked perfectly on the good donor Disco so we have ruled out the sensor itself.

Checked the wiring loom on top of the gearbox for any chafing, which there isn't and also checked for continuity on all the wires from the XYZ sensor and the other transmission wires running through the loom back to the connector blocks under the centre console. All have good continuity.

Swapped the gearbox ECU off the good Disco onto the poorly one. It made no difference and the one off the poorly one works fine on the good one.

When trying both front front windows there are no relay clicking sounds coming from the BCU module. Both windows worked correctly before the green flashing transmission warning lights appeared.

Checked the battery voltage and ran a direct earth from the battery to the BCU and gearbox loom earthing points. Made no difference.

Could it be a faulty BCU or damage to the wiring somewhere between the centre console and the passenger footwell where the BCU is located?

Any other ideas?

Is it possible to swap out the BCU on a plug and play basis with a known fully functional one or would we need to use Nanocom to configure it? Thinking we could try the BCU off the working Disco.

The fact that the front windows are controlled by the BCU and also the XYX sensor is linked to the BCU makes me think the gearbox and electric window faults are not coincidental and must be related.

I've googled the topic to death and can't find any info on a combination of P0705 fault codes and dead front electric windows.

Any pointers would be much appreciated!!!!!!

Thanks