roule

Active Member

J'ai du mal à comprendre les mesures.

Vos chiffres affichés semblent être plus qu'une « nouvelle norme » ?

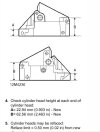

I put the wrong photo. For a non suffix B engine its 23,9 mm and 63,5 mm . I get 23,30 and 62,809 with my vernier caliper...I am having trouble getting my head around the measurements.

Your posted numbers seem to be more than "new standard"?

J

For those specs & measurements, clearly it's already been skimmed at some point. As long as it's clean & not warped you should be ok.

Best invest in decent gaskets such as Elring, plus use ARP Studs. You probably need the 28 stud kit, but check your engine.

Best place I found in UK is Real Steel, Cowley.

Best invest in decent gaskets such as Elring, plus use ARP Studs. You probably need the 28 stud kit, but check your engine.

Best place I found in UK is Real Steel, Cowley.

They are just up the road from me. Very helpful guys on the counter.Interesting that Real Steel are still around. They used to market a kit to stroke the 3.5 to 4.3; I knew a guy years ago that did this & the thing pulled so hard it proved too much for the ZF

Used the Elring composites on mine (1986 3.5EFi Classic).

Heads had had a small amount skimmed, can't remember the amount but it was single figures.

Reassembled using the Elrings & the covered valley gasket.

No issues & didn't need to shim the rocker towers.

Haven't noticed any reduction in power but I did replace the cam, the followers, timing chain & sprockets at the same time.

Recommendation is to leave out the outer row of bolts as there is some suggestion they cause the heads to tip slightly - must be something in it as LR did away with that row & later heads don't even have the holes for them.

Either throw in the bin or, if you want to fill the holes, just nip them up lightly.

Heads had had a small amount skimmed, can't remember the amount but it was single figures.

Reassembled using the Elrings & the covered valley gasket.

No issues & didn't need to shim the rocker towers.

Haven't noticed any reduction in power but I did replace the cam, the followers, timing chain & sprockets at the same time.

Recommendation is to leave out the outer row of bolts as there is some suggestion they cause the heads to tip slightly - must be something in it as LR did away with that row & later heads don't even have the holes for them.

Either throw in the bin or, if you want to fill the holes, just nip them up lightly.

roule

Active Member

Thanks. My gasket is a tin one from Payen (not Erlring)J'ai utilisé les composites Elring sur le mien (1986 3.5EFi Classic).

Les têtes avaient eu un petit montant écrémé, je ne me souviens plus du montant, mais il s'agissait d'un chiffre unique.

Remonté à l'aide des Elrings et du joint de vallée couvert.

Aucun problème et pas besoin de caler les tours à bascule.

Je n'ai remarqué aucune réduction de puissance mais j'ai remplacé la came, les suiveurs, la chaîne de distribution et les pignons en même temps.

La recommandation est de laisser de côté la rangée extérieure de boulons, car il semblerait qu'ils fassent légèrement basculer les têtes - il doit y avoir quelque chose dedans car LR a supprimé cette rangée et les têtes ultérieures n'ont même pas de trous pour elles.

Jetez-les à la poubelle ou, si vous souhaitez combler les trous, pincez-les légèrement.

roule

Active Member

i checked the head flatness with a special tool (300 mm ruler grade 00).

All is under 0,05 mm gap EXCEPT the two ends where i found 0,08 mm difference (red part on the pictures) when I take the measurement with 300mm length of the ruler (from the center to the end)

If i take the measure with only 200 mm of the ruler, from the end it's ok, i have less than 0,05 mm gap.

Could i fill this gap with the head torque ? : little less torque in the middle (65 ft) , little more at the ends (70ft) ...is it a right way with a convex head ?

All is under 0,05 mm gap EXCEPT the two ends where i found 0,08 mm difference (red part on the pictures) when I take the measurement with 300mm length of the ruler (from the center to the end)

If i take the measure with only 200 mm of the ruler, from the end it's ok, i have less than 0,05 mm gap.

Could i fill this gap with the head torque ? : little less torque in the middle (65 ft) , little more at the ends (70ft) ...is it a right way with a convex head ?

Attachments

Last edited:

checked the head flatness with a special tool (300 mm ruler grade 00).

All is under 0,05 mm gap EXCEPT the two ends where i found 0,08 mm difference (red part on the pictures) when I take the measurement with 300mm length of the ruler (from the center to the end)

If i take the measure with only 200 mm of the ruler, from the end it's ok, i have less than 0,05 mm gap.

Could i fill this gap with the head torque ? : little less torque in the middle (65 ft) , little more at the ends (70ft) ...is it a right way with a convex head ?

You should really use a longer ruler, that's long enough for the entire head.

I would only try to torque that down with ARP Studs & composite gasket, rather than a flat steel one. Stretch bolts could overstress the block threads.

Although in thoery your head is already at the skim limit, you would probably get away with another 0.1mm to 0.15mm, provided you use composite gaskets.

roule

Active Member

I read a lot of leaks at the ends of the heads (near water holes) even with elring composite HG ...frighten me a little.Right i should change for Composite HG , and reuse my standard bolts...there still in good shape and not overtightened the last time.

roule

Active Member

I don't have enough material to mill thurther. I could try to straighten the head on the block with only the ends bolts and a A4 paper under the middle head...then I check the gap with my 0,05 mm gauge .Then get it properly flat. Also check block flatness.

Do the measurement with a longer ruler. If it's within 0.05mm, then you should be ok.

Check the engine number for the correct gasket type. Apparently there are three gasket thicknesses available. In you case I would use the thicker one.

As I said, either use ARP Studs, or New Stretch Bolts. Do not re-use the old bolts !!

--------------------

Check the engine number for the correct gasket type. Apparently there are three gasket thicknesses available. In you case I would use the thicker one.

As I said, either use ARP Studs, or New Stretch Bolts. Do not re-use the old bolts !!

--------------------

roule

Active Member

I have more than 0,05 on the 2 ends, my head is bowed at the center.ARP are too expensive and i 'm not confident with streched ones. I should use a composite gasket with new standard bolts...Do the measurement with a longer ruler. If it's within 0.05mm, then you should be ok.

Check the engine number for the correct gasket type. Apparently there are three gasket thicknesses available. In you case I would use the thicker one.

As I said, either use ARP Studs, or New Stretch Bolts. Do not re-use the old bolts !!

--------------------

View attachment 312764 View attachment 312765