ThomasLRNL

Active Member

Hello all,

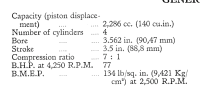

I am redoing this 2.25 petrol, and I find that the piston rings are probably very worn out. Can someone tell me according to these pictures if new rings are needed; or a complete new piston? Thanks! Personally i think new rings, since on the piston themselves they have a gap too. Indicating that they need to be pushed further in to have no/a smaller gap. if these are fine/engine will run with them. Id like to know too! It doesnt have to be a performance monster i just want it running.

Please let me know!

I am redoing this 2.25 petrol, and I find that the piston rings are probably very worn out. Can someone tell me according to these pictures if new rings are needed; or a complete new piston? Thanks! Personally i think new rings, since on the piston themselves they have a gap too. Indicating that they need to be pushed further in to have no/a smaller gap. if these are fine/engine will run with them. Id like to know too! It doesnt have to be a performance monster i just want it running.

Please let me know!