Hello I have a question... got a K series freelander that it's weird on compression and idle after head gasket job.

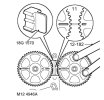

I did see the cams were a bit tatty, the question is how can I tell which is inlet and outlet? the part numbers are different in microcat but as far as I remember casing marks are the same. They also look the same.

I suspect they might be fitted incorrectly on previous job which was a bodgit...

I have another nice pair of cams ready for the weekend just want to make sure I am doing it correctly.

I did see the cams were a bit tatty, the question is how can I tell which is inlet and outlet? the part numbers are different in microcat but as far as I remember casing marks are the same. They also look the same.

I suspect they might be fitted incorrectly on previous job which was a bodgit...

I have another nice pair of cams ready for the weekend just want to make sure I am doing it correctly.