-

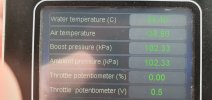

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Right I'd say she's way off at 86.57% modulation at 94.40⁰c. So from this can we extrapolate which direction the pump should be rotated?

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Right I'd say she's way off at 86.57% modulation at 94.40⁰c. So from this can we extrapolate which direction the pump should be rotated? -

UnitLandy reacted to Flossie's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to Flossie's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withLike.

Deffo do the nano thing. You may find a reluctant hot start and a lumpy idle if modulation is out, and idle is returned to c750 rpm. -

UnitLandy reacted to Rubberknees's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to Rubberknees's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withLike.

👍 👍 👍 :banana: -

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Thanks guys. As it happens I went ahead without the nanocom & loosened the mid 4 FIP bolts and tapped the actuator forwards with a hammer & it's running sweet as a nut now (aren't hammers just the best thing ever 😄 🤣 😂). I'll get some readings...

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Thanks guys. As it happens I went ahead without the nanocom & loosened the mid 4 FIP bolts and tapped the actuator forwards with a hammer & it's running sweet as a nut now (aren't hammers just the best thing ever 😄 🤣 😂). I'll get some readings... -

UnitLandy reacted to Flossie's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to Flossie's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withLike.

To read modulation the engine has to be running at max temp. You're looking for 50% for perfection but a bit either side of that doesn't make any real differance. -

UnitLandy reacted to pwood999's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to pwood999's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withLike.

Not got a diseasel, but go into EDC / Inputs / 2nd screen. Look for Modulation ?? -

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Thanks lads. Right I've got my brothers Nanocom but I've never used one before. I belive it's set up already but I've no idea which menu selections I need to use. Could someone guide me through, cheers? Yes I put grooves on the back of the mid...

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Thanks lads. Right I've got my brothers Nanocom but I've never used one before. I belive it's set up already but I've no idea which menu selections I need to use. Could someone guide me through, cheers? Yes I put grooves on the back of the mid... -

UnitLandy reacted to ovalandrover's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to ovalandrover's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withLike.

as for the bolt in the side of the pump it ist here to be used when there is a mechanical governor when the VE pump is used on other aplications -

UnitLandy reacted to Mark Piercy's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to Mark Piercy's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withLike.

That's an easy mistake a good few of us have made🤣 -

UnitLandy reacted to RangeRoller dt's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to RangeRoller dt's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withLike.

If modulation is good I’m starting to think mid section. Hopefully the ball is in the cup properly -

UnitLandy reacted to Grrrrrr's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to Grrrrrr's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withLike.

Only on one side? Might be worth twisting ever so slightly while engine is running and someone is ready to kill it. -

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.It's been rebuilt. I put three grooves into to aid alignment. After rebuild.

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.It's been rebuilt. I put three grooves into to aid alignment. After rebuild. -

UnitLandy reacted to Grrrrrr's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to Grrrrrr's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withLike.

I wouldn't touch the top of that pump unless it has been off. Just the act if retightening can affect the idle. It is very sensitive. You'll need a volunteer in the car ready to kill the engine if you tap it too far and it starts revving its nuts... -

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Cheers, I remembered that!

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Cheers, I remembered that! -

UnitLandy reacted to RangeRoller dt's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to RangeRoller dt's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withLike.

However you adjust the pump angle, the final movement of adjustment must be toward the engine. -

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.yes, sorry. 900rpm not 90. My brother has the nanocom. I'll see if I can get a reading when he comes round.

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.yes, sorry. 900rpm not 90. My brother has the nanocom. I'll see if I can get a reading when he comes round. -

UnitLandy reacted to Datatek's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to Datatek's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withLike.

No good guessing, what modulation figure do you have with the engine hot? I assume that you mean 900 rpm not 90? -

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Right, got her running but she's very lumpy & idling at around 90rpm. So does that mean I need to slightly loosen the second row of bolts on the FIP and knock it forwards a touch. Guess the pump needs to be rotated anticlockwise a touch too. I'm...

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Right, got her running but she's very lumpy & idling at around 90rpm. So does that mean I need to slightly loosen the second row of bolts on the FIP and knock it forwards a touch. Guess the pump needs to be rotated anticlockwise a touch too. I'm... -

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Right it's back in. It felt okay - no resistance. Here's a before picture of the woodruff key before I removed it: And here's after: Does that look okay to you? Just checking... Nearly forgot to put the brass nut on at 50NM before pulling...

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Right it's back in. It felt okay - no resistance. Here's a before picture of the woodruff key before I removed it: And here's after: Does that look okay to you? Just checking... Nearly forgot to put the brass nut on at 50NM before pulling... -

UnitLandy reacted to Mark Piercy's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to Mark Piercy's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withLike.

It could be a setting up port for the factory 🤔 -

UnitLandy reacted to Mark Piercy's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to Mark Piercy's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withLike.

I wouldn't have thought so the system self bleeds with the in tank pump running. -

UnitLandy reacted to Mark Piercy's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to Mark Piercy's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withHaha.

Put nail varnish on em...😜 -

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Could the bolt be a bleed nut?

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Could the bolt be a bleed nut? -

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Bet the engineers didn't know either. Just thought it looks nice. Rustic...

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Bet the engineers didn't know either. Just thought it looks nice. Rustic... -

UnitLandy reacted to Mark Piercy's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to Mark Piercy's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withHaha.

No idea for the other bits kiddo🤔 -

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Right. I just went ahead & did it; 90NM for the threaded inspection bung, 25NM for the inspection bolt & 45NM for the delivery value holders. All went well. FYI: I didn't torque it up like this. I had the steel end nipped up in the vice not the...

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Right. I just went ahead & did it; 90NM for the threaded inspection bung, 25NM for the inspection bolt & 45NM for the delivery value holders. All went well. FYI: I didn't torque it up like this. I had the steel end nipped up in the vice not the... -

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Cheers! I think these are the correct RAVE torque settings for the FIP but I can't see the correct torque for the larger threaded bung.

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.Cheers! I think these are the correct RAVE torque settings for the FIP but I can't see the correct torque for the larger threaded bung. -

UnitLandy reacted to Grrrrrr's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? with

UnitLandy reacted to Grrrrrr's post in the thread P38 Diesel Injector Pump & Cam Top Dead Centre? withLike.

I'd have to check RAVE next time I have the laptop running but it is less than you think. 90 nm sounds way too much. 25 nm sounds more likely. The high pressure pipes just need nipping up so they don't leak. Finger tips tight using a 17 mm... -

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.How do! Three weeks later & not much done. Been waiting on a workbench to attach a vice properly which took the best part of two weeks while I also accidentally ordered just one metal advance gasket which meant waiting another week. I've got...

UnitLandy replied to the thread P38 Diesel Injector Pump & Cam Top Dead Centre?.How do! Three weeks later & not much done. Been waiting on a workbench to attach a vice properly which took the best part of two weeks while I also accidentally ordered just one metal advance gasket which meant waiting another week. I've got...